Description

Number of Pages: 136

This is a brand new original Useful Machine Shop Tools to Make for Home Shop Machinists. This book is part of our Workshop Machinists Series that we started carrying, because we found them helpful in our shop. We have the entire collection in our library and found that many of our customers found them useful too.

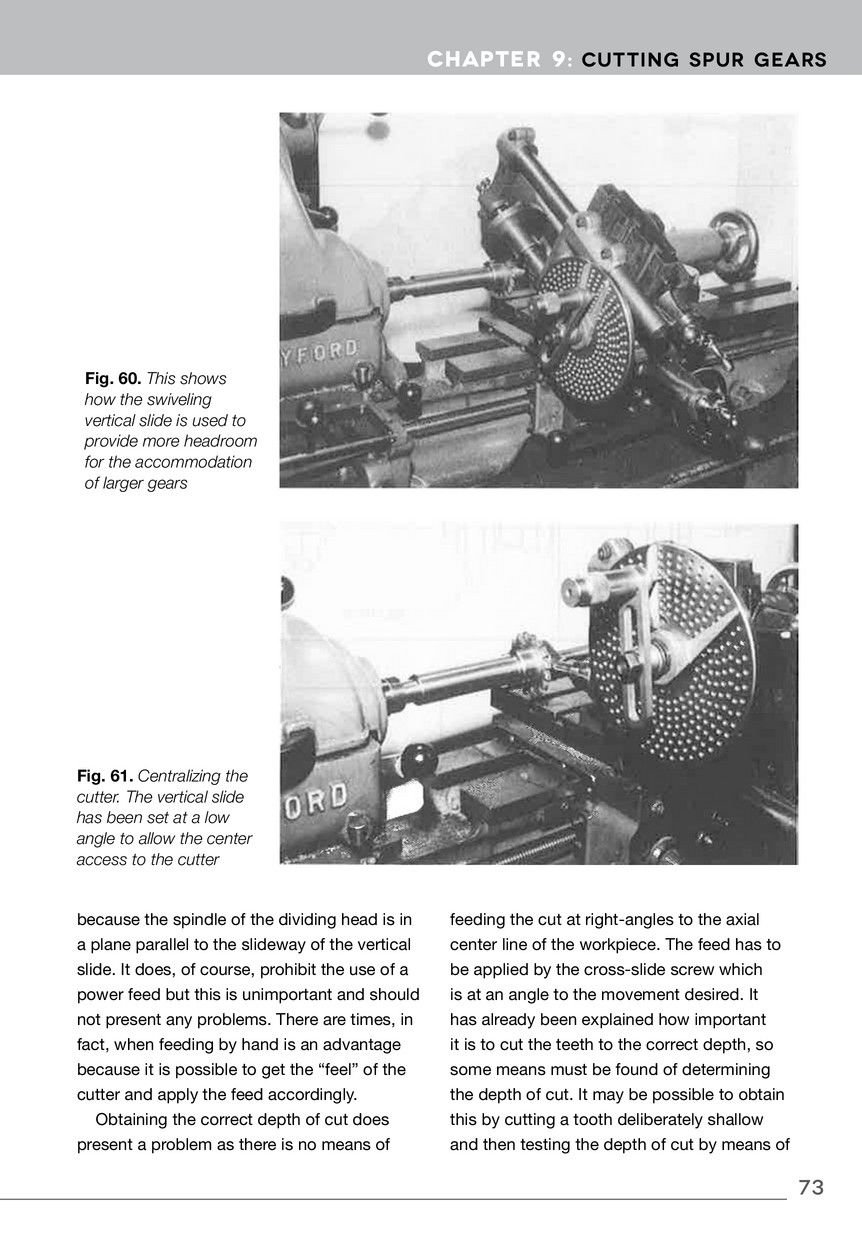

This practical, hands-on guide will assist anyone who wants to cut gears inexpensively on a lathe or milling machine.

- Learn the fundamentals needed to design your own gears and gear trains

- Understand the complexity of gears and how to machine them, in a very clearly presented and easy to understand way

- Plain, simple and non-technical language, with the mathematics kept to the simplest form

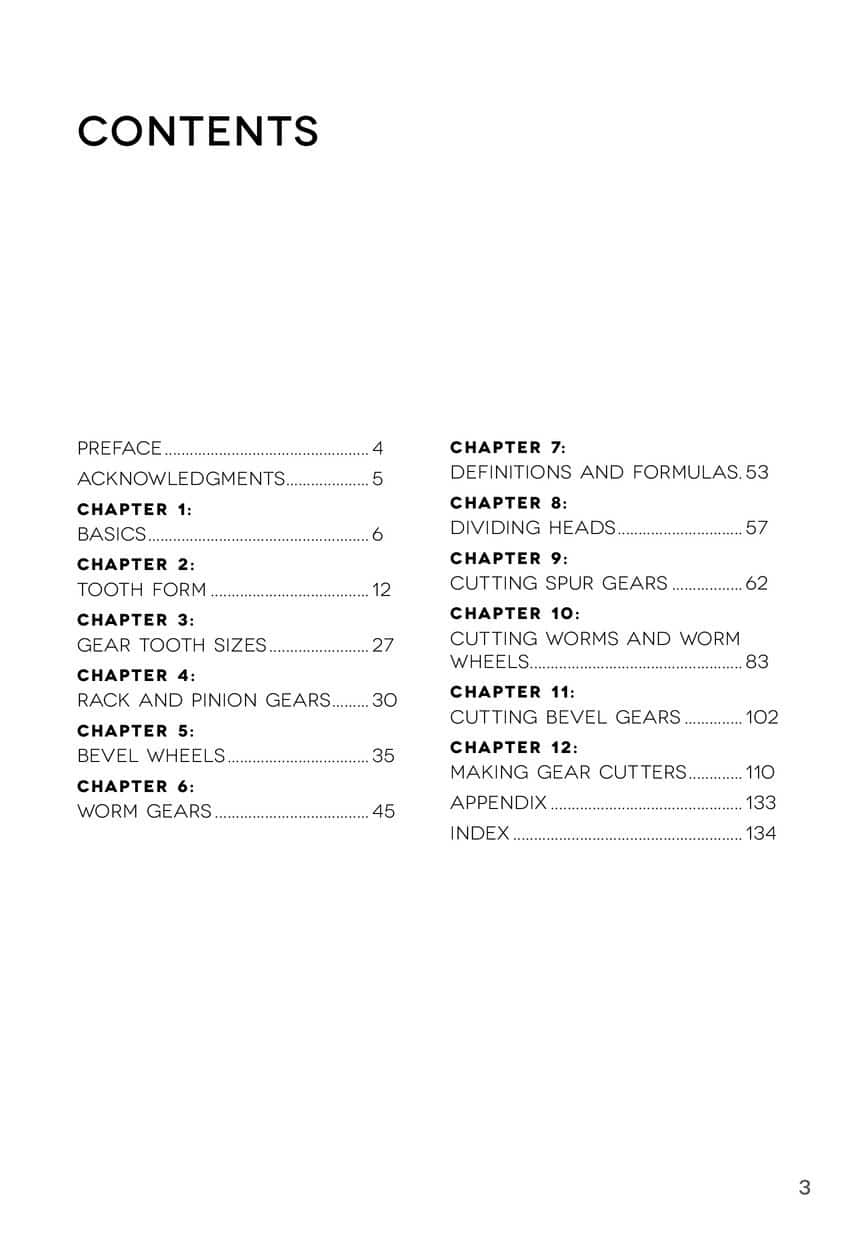

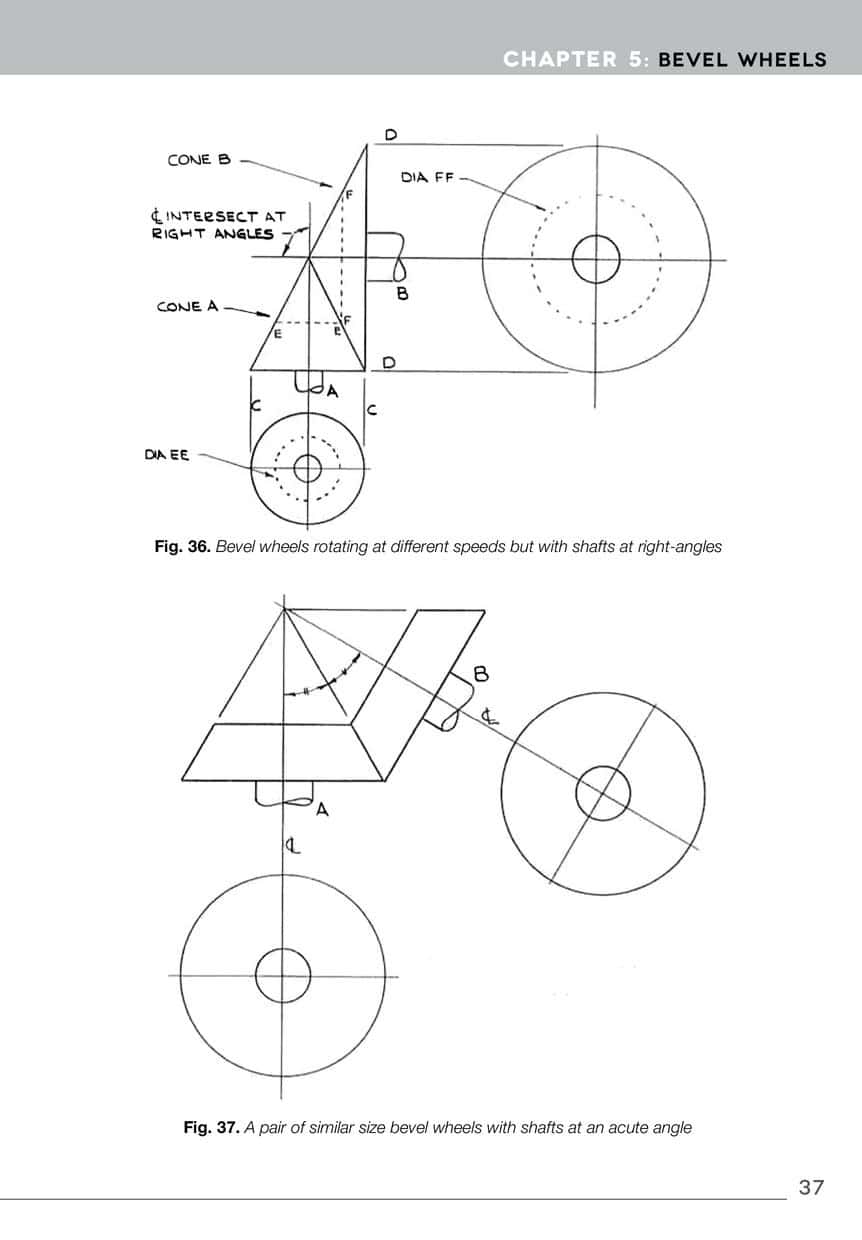

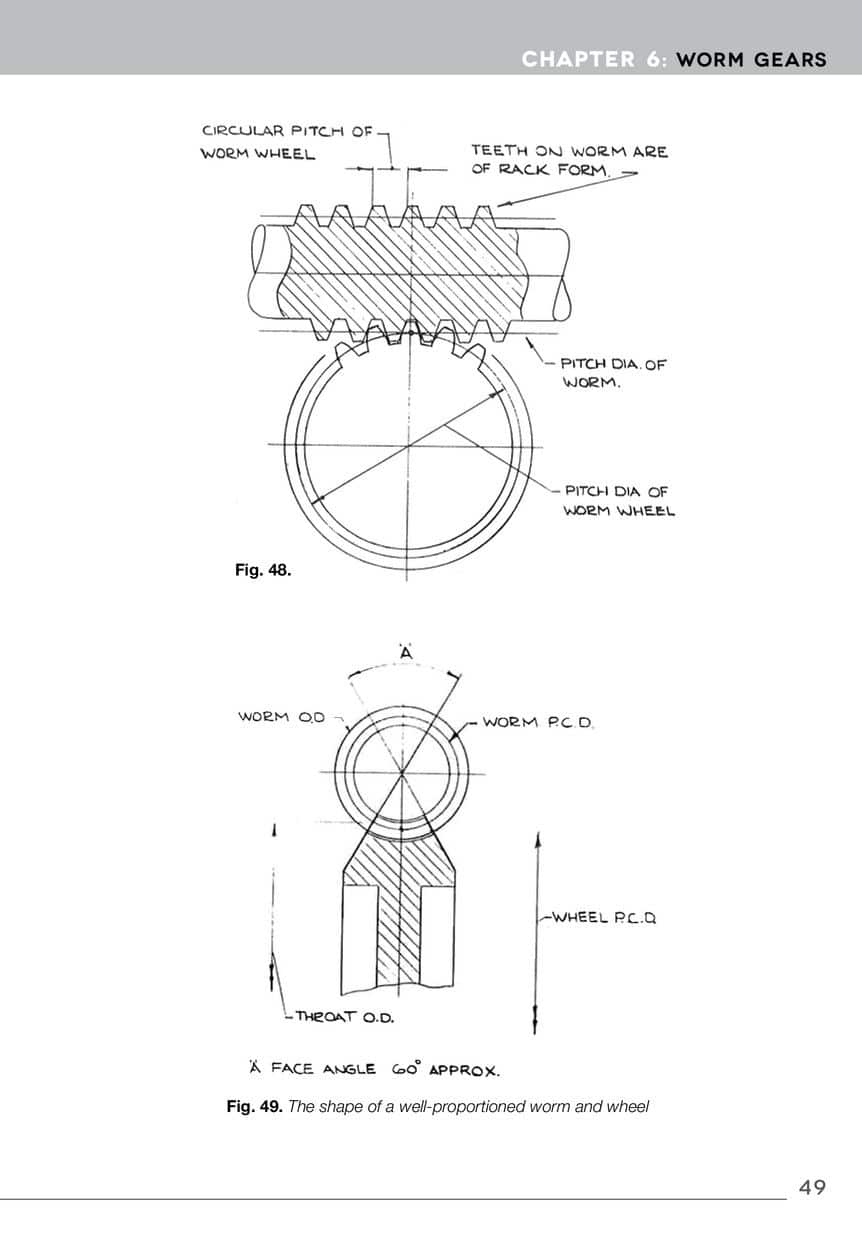

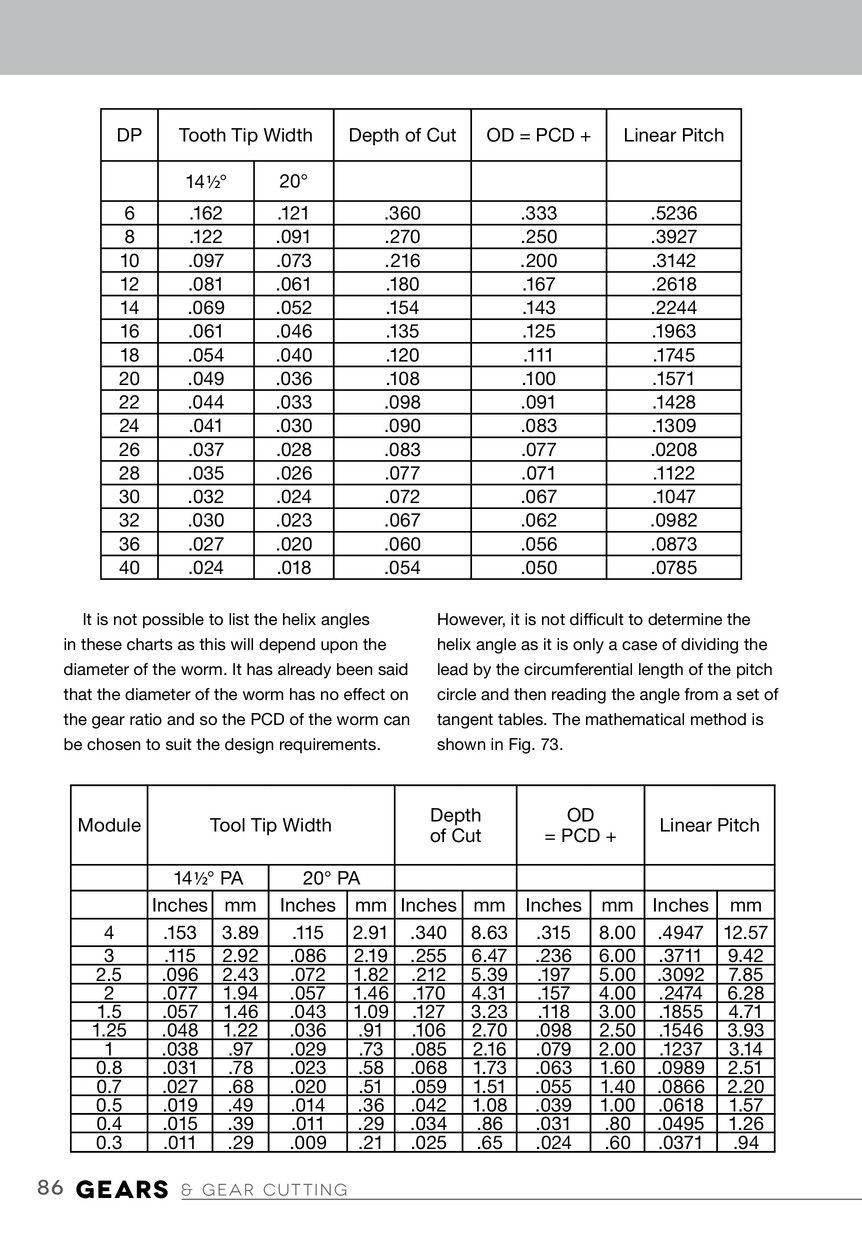

- Information on tooth forms & sizes, rack & pinion gears, bevel wheels, making gear cutters, and more

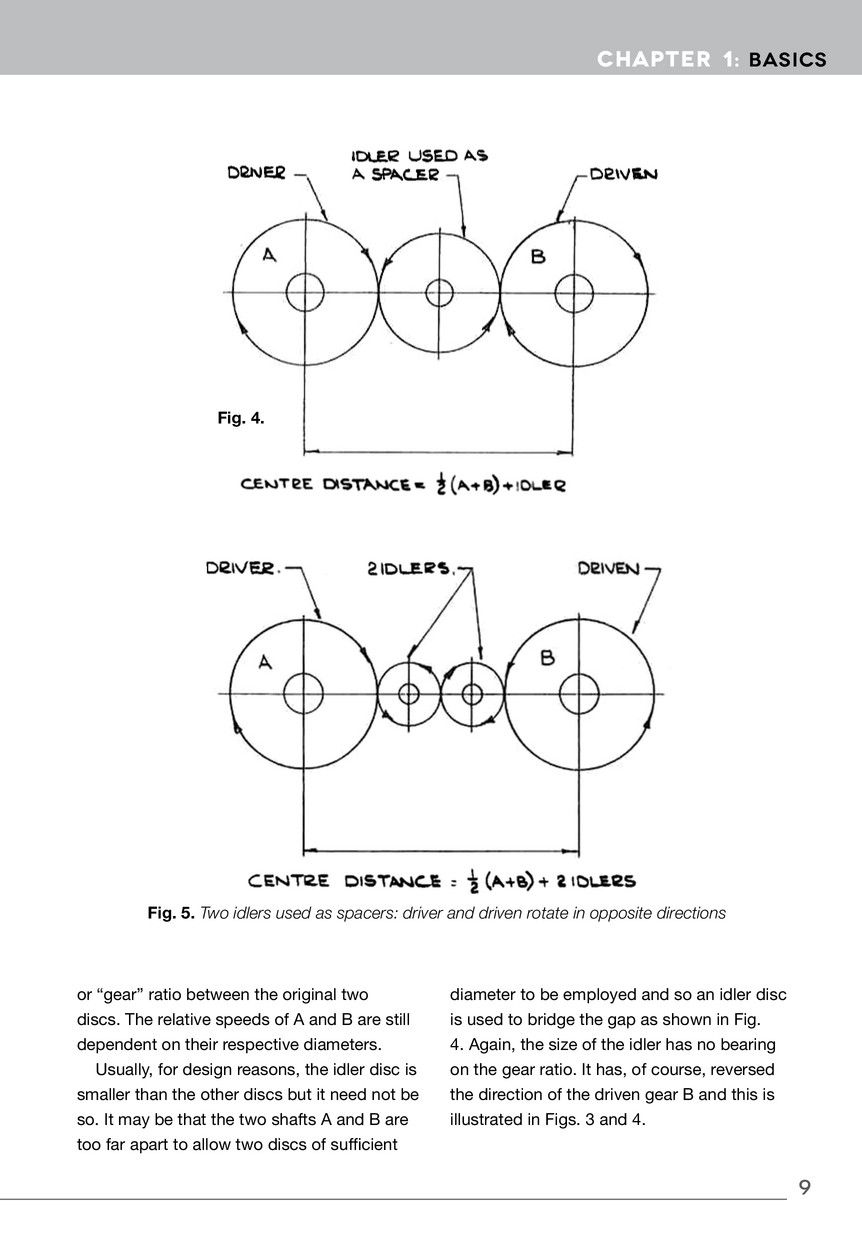

- Well-illustrated with concise technical diagrams and B&W photos

Gears in one form or another are a part of most mechanisms, but they are by no means as simple as they appear!

Gears & Gear Cutting for Home Machinists is a practical, hands-on guide for anyone who wants to cut gears inexpensively on a lathe or milling machine. This book teaches the fundamentals needed to design gears and gear trains using plain, simple, non-technical language that keeps the level of mathematics down to its simplest form. It covers all the questions raised by enthusiasts who have watched the author demonstrating gear-cutting techniques at exhibitions throughout Britain, where his advice on engineering matters is constantly sought.

With information on tooth forms & sizes, rack & pinion gears, bevel wheels, making gear cutters, and more, Gears & Gear Cutting for Home Machinists is well illustrated with concise technical diagrams and photographs.

—George Bulliss,

The Home Shop Machinist magazine

The Workshop Machinists Series

Buy 3 or more books from the Workshop Machinists Series, and receive a

10% discount, plus Free domestic shipping.

Discount it automatically applied at checkout.

Or purchase the complete set.