Description

Number of Pages: 114

This is a reproduction, not a photocopy, of an original Cincinnati Toolmaster Milling Machine 1B, 1C, 1D, 1E, H-V Service and Parts Manual. This manual contains general safety instructions, operation instructions, adjustments, maintenance, and a complete set of exploded view part diagrams with descriptions. See index below.

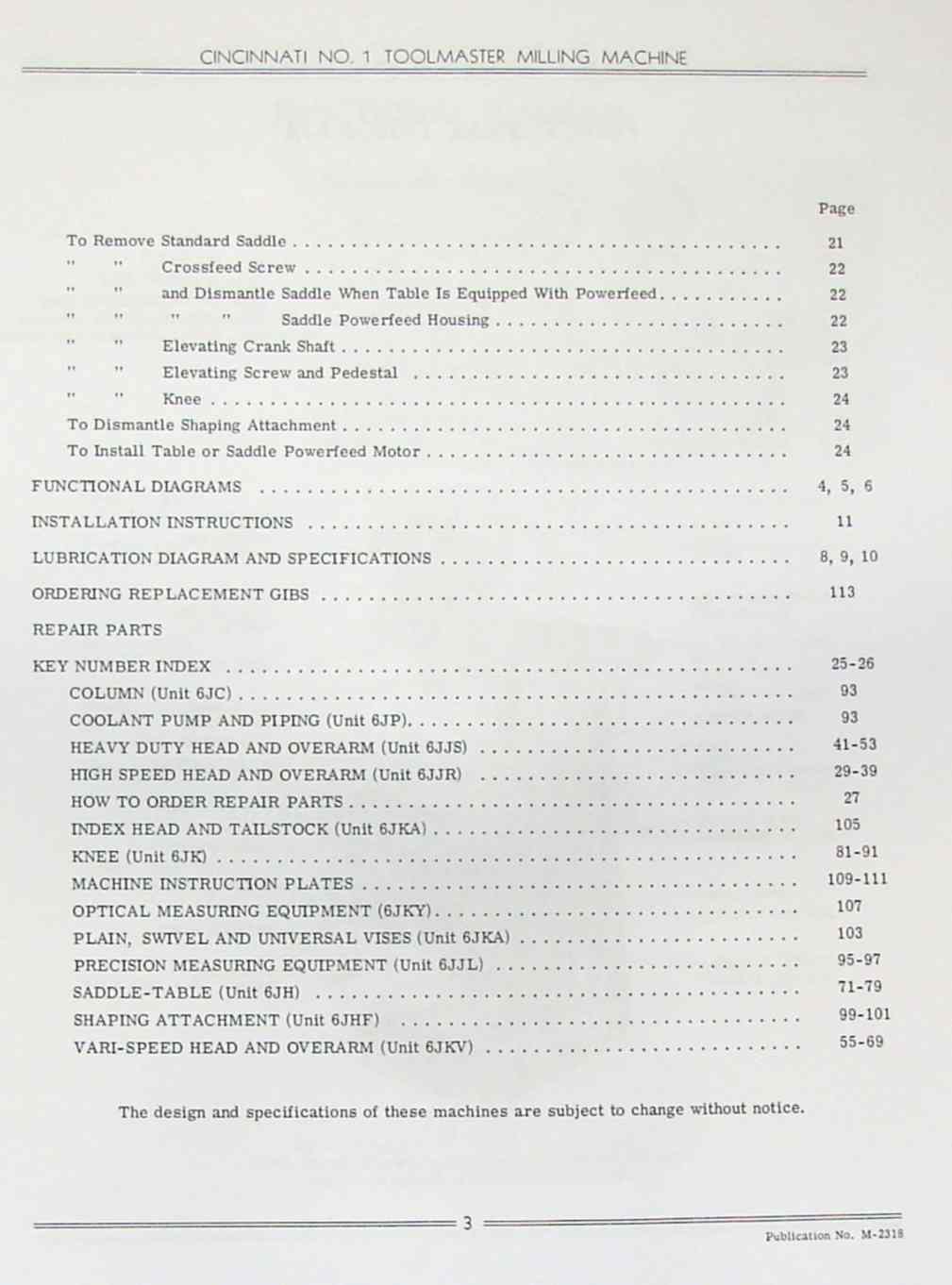

Contents:

ADJUSTMENTS To Adjust Arbor Support Bushing...........................................3 " " Backlash Eliminator............................................12 " " Drive Belts: Style 1-B.........................................12 " " Drive Belt: Style 1-E..........................................12 " " Gibs...........................................................12 " " Quill Powerfeed Clutch: Style 1-B..............................12 " " Shaping Attachment Drive Belt..................................12 " " Shaping Attachment Gib.........................................12 CONVERSION CHART(Inches to M/M).........................................112 DIMENSIONAL DRAWINGS....................................................6,7 DISMANTLING INSTRUCTIONS To Remove V-Belt Housing: Style 1-B......................................13 " " " " : Style 1-D......................................13 " " " " : Style 1-E......................................13 " " Splined Spindle Sleeve: Style 1-B..............................13 " " Drive Spindle Assembly: Style 1-B..............................14 " " " " : Styles 1-D, 1-E................................15 " " Spindle Housing with Spindle: Style 1-B........................15 " " " " : Styles 1-D, 1-E................................16 " " Spiral Gear Shaft: Style 1-B...................................16 " " Transmission Shaft: Style 1-B..................................16 " " Speed Change Assembly: Style 1-D...............................17 " " and Dismantle Powerfeed Housing: Styles 1-D, 1-E...............17 " " Overarm and Turret: Styles 1-B, 1-D, 1-E.......................18 " " Overarm (Heavy Duty): Styles 1-C, H-V..........................18 " " and Dismantle Overarm Gear Housing: Styles 1-C, H-V............18 " " Spindle Housing and Drive - Without Hand Feed: Styles 1-C, H-V.18 " " Spindle Housing and Drive -With Hand Feed: Styles 1-C, H-V.....19 " " and Dismantle Intermediate Swivel Housing: Styles 1-C, H-V.....19 " " Table..........................................................19 " " Table Leadscrew................................................20 " " Powerfeed Housing..............................................20 To Dismantle Table Powerfeed Housing.....................................21 To Remove Standard Saddle................................................21 " " Crossfeed Screw................................................22 " " and Dismantle Saddle When Table Is Equipped With Powerfeed.....22 " " " " Saddle Powerfeed Housing.........................22 " " Elevating Crank Shaft..........................................23 " " Elevating Screw and Pedestal ..................................23 " " Knee...........................................................2 To Dismantle Shaping Attachment..........................................24 To Install Table or Saddle Powerfeed Motor...............................24 FUNCTIONAL DIAGRAMS ..................................................4,5,6 INSTALLATION INSTRUCTIONS ...............................................11 LUBRICATION DIAGRAM AND SPECIFICATIONS...............................8,9,10 ORDERING REPLACEMENT GIBS...............................................113 REPAIR PARTS KEY NUMBER INDEX.........................................25-26 COLUMN (Unit 6JC)........................................................93 COOLANT PUMP AND PIPING (Unit 6JP).......................................93 HEAVY DUTY HEAD AND OVERARM (Unit 6JJS)...............................41-53 HIGH SPEED HEAD AND OVERARM (Unit 6JJR)...............................29-39 HOW TO ORDER REPAIR PARTS................................................27 INDEX HEAD AND TAILSTOCK (Unit 6JKA)....................................105 KNEE (Unit 6JK).......................................................81-91 MACHINE INSTRUCTION PLATES..........................................109-111 OPTICAL MEASURING EQUIPMENT (6JKY)......................................107 PLAIN, SWIVEL AND UNIVERSAL VISES (Unit 6JKA)...........................103 PRECISION MEASURING EQUIPMENT (Unit 6JJL).............................95-97 SADDLE-TABLE (Unit 6JH)...............................................71-79 SHAPING ATTACHMENT (Unit 6JHF)...................................... 99-101 VARI-SPEED HEAD AND OVERARM (Unit 6JKV)...............................55-69

Overview

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page,and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear; they are then comb bound with heavy cover pages so they lie flat on the workbench.