Description

Number of Pages: 42

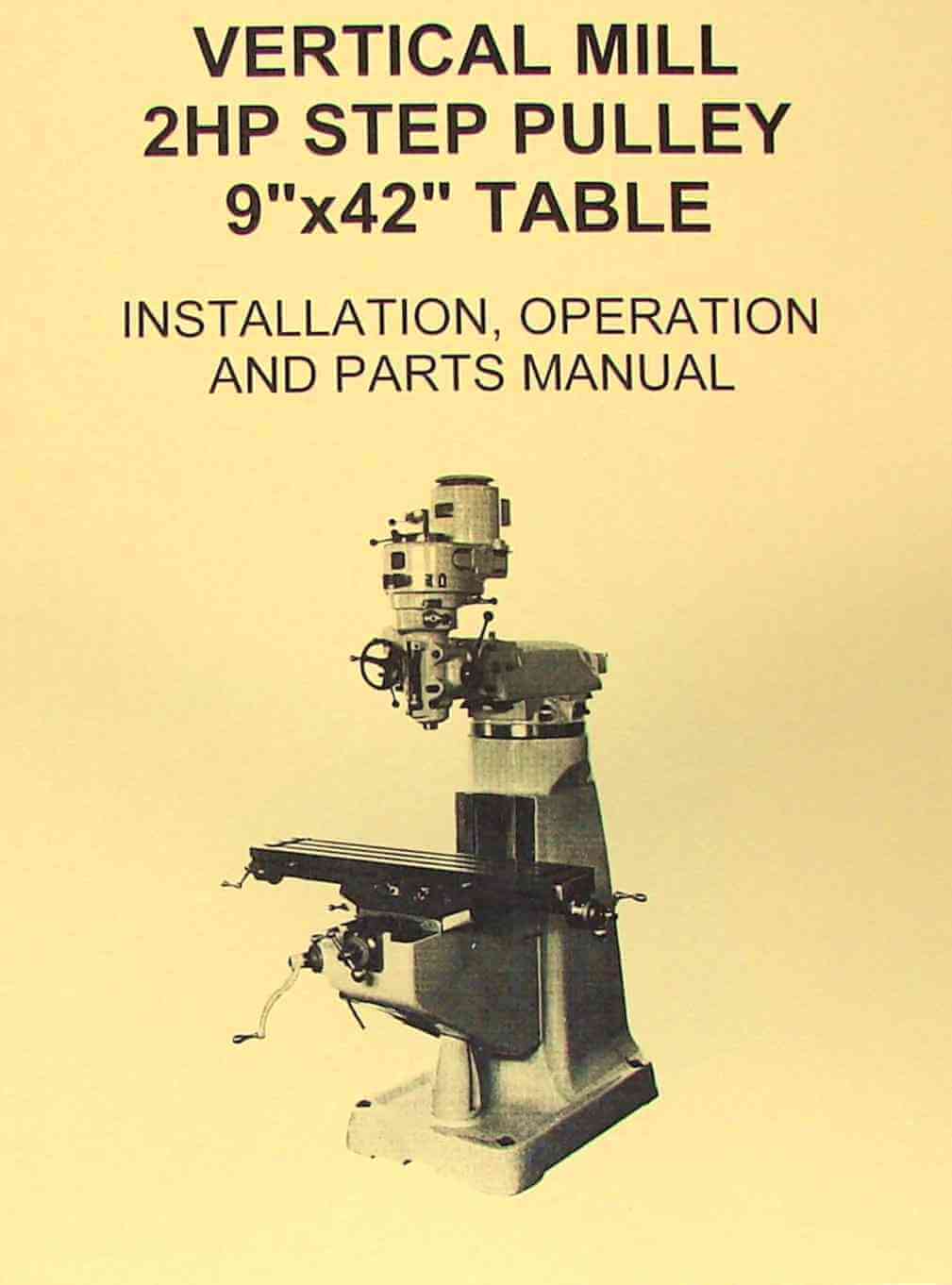

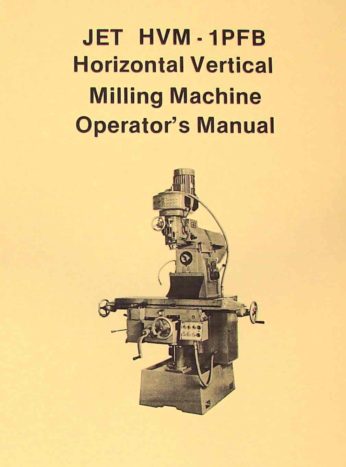

This is a reproduction, not a photocopy, of an original Asian Vertical Mill 9″x42″ Step Pulley Installation and Parts Manual. This machine is manufactured in Asia and has been sold under many different names including: JET, Grizzly, Enco , MSC, etc… This manual contains information on setup, lubrication, maintenance, and controls as well as a complete parts list.

Known Models:

JET JVM-942

Enco 92050

Picture:

Specifications:

|

Stock No.: |

690066 |

Collet Capacity: |

1/8″-3/4″X |

|

Spindle Taper: |

R-8 |

|

1/16″ |

|

Number of |

|

Size of Table: |

9″x42″ |

|

Spindle Speeds: |

8 |

No. of T-Slots |

|

|

Range of |

|

in Table: |

3 |

|

Spindle Speeds |

|

Width & Centers |

|

|

(RPM): |

80-2720 |

of T-Slots: |

5/8 at |

|

Quill Feeds Per |

|

|

2 1/2 “ |

|

Rev. of |

0.0015″- |

Ram Movement: |

12″ |

|

Spindle: |

0.003″- |

Longitudinal |

|

|

|

0.006″ |

Traverse: |

30″ |

|

Spindle Travel: |

5″ |

Cross Traverse: |

12″ |

|

Max. Distance |

|

Vertical Traverse: |

16″ |

|

Spindle to Table: |

19″ |

Floor Space: |

64″x82″ |

|

Max. Distance |

|

Motor: |

2HP,3Ph |

|

Spindle to |

|

|

220/440V |

|

Column: |

19″ |

|

(Prewired |

|

Min. Distance |

|

|

220V) |

|

Spindle to |

|

Net Weight |

|

|

Column: |

6 3/4″ |

lbs. (approx.): |

1962 |

Contents:

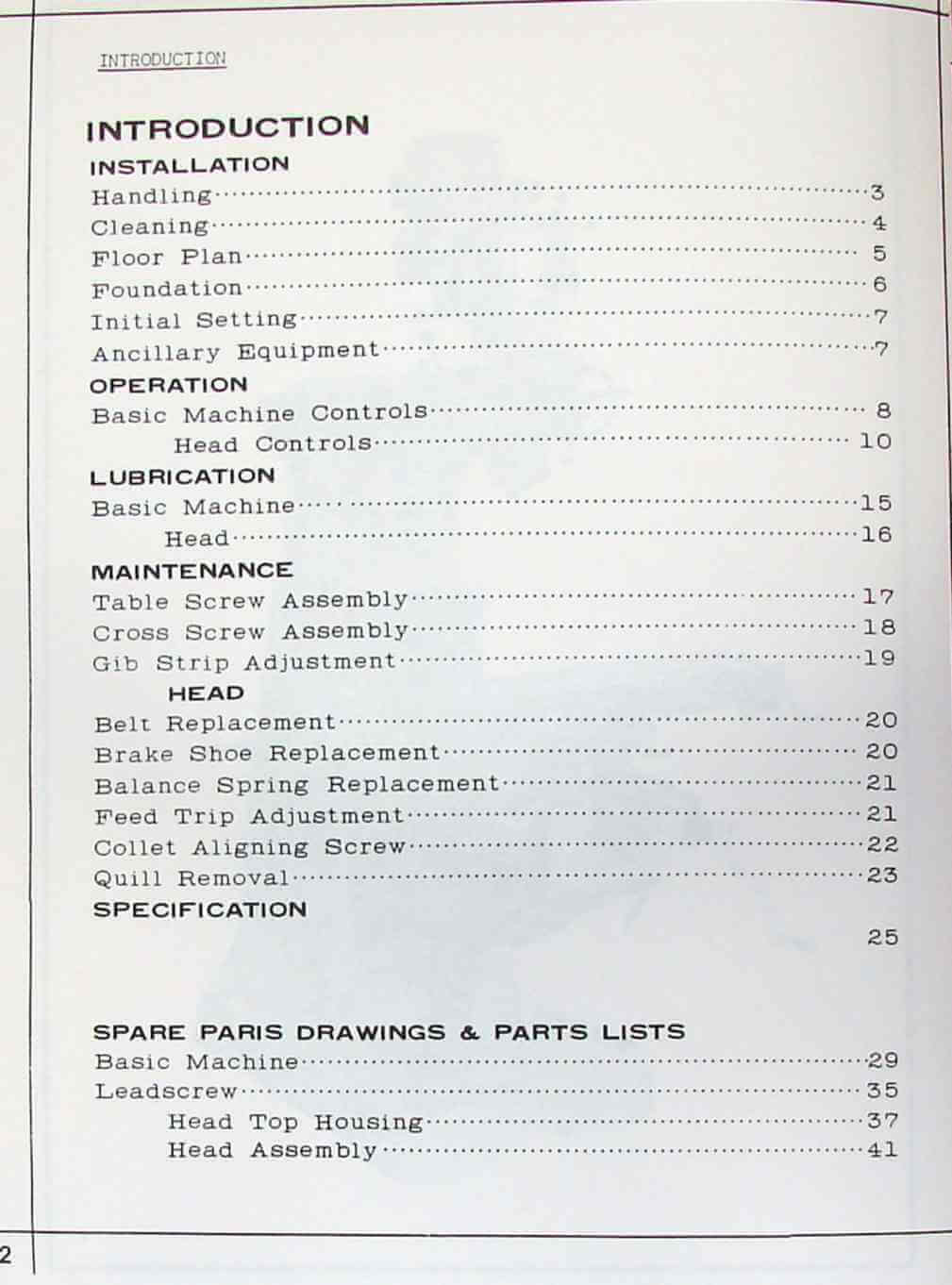

| INTRODUCTION | |

|

Handling………………………………………………………………… |

3 |

| Cleaning………………………………………………………………… | 4 |

| Floor Plan……………………………………………………………… | 5 |

| Foundation…………………………………………………………….. | 6 |

| Initial Setting…………………………………………………………… | 7 |

| Ancillary Equipment…………………………………………………. | 7 |

|

OPERATION |

|

| Basic Machine Controls……………………………………………. | 8 |

| Head Controls………………………………………………………… | 10 |

|

LUBRICATION |

|

| Basic Machine………………………………………………………… | 15 |

| Head…………………………………………………………………….. | 16 |

|

MAINTENANCE |

|

| Table Screw Assembly…………………………………………….. | 17 |

| Cross Screw Assembly……………………………………………. | 18 |

| Gib Strip Adjustment……………………………………………….. | 19 |

|

HEAD |

|

|

Belt Replacement……………………………………………………. |

20 |

|

Brake Shoe Replacement…………………………………………. |

20 |

| Balance Spring Replacement……………………………………… | 21 |

| Feed Trip Adjustment………………………………………………. | 21 |

| Collet Aligning Screw………………………………………………. | 22 |

| Quill Removal…………………………………………………………. | 23 |

|

SPECIFICATION………………………………………………….. |

25 |

|

SPARE PARIS DRAWINGS & PARTS LISTS |

|

| Basic Machine………………………………………………………… | 29 |

| Leadscrew…………………………………………………………….. | 35 |

| Head Top Housing………………………………………………….. | 37 |

| Head Assembly………………………………………………………. | 41 |

|

The manual above may help you operate and maintain your milling machine, but if you would like to learn more about how to set up and use your mill properly, I highly recommend you check out this book here: The Milling Machine for Home Machinists Book. It covers how to properly install, and check for alignment of the table and spindle illustrated in color photographs and diagrams. It goes into the basics of how to clamp down different shaped material. This information can even be useful for experienced mill operators. You’ll wish this was the manual that originally came with your mill with its no-nonsense approach. We also have a complete series of different machinist books on sharpening, gearmaking, metal lathes, and more here: Workshop Machinist Series |

|

|---|

Overview:

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear.