Description

Number of Pages: 32

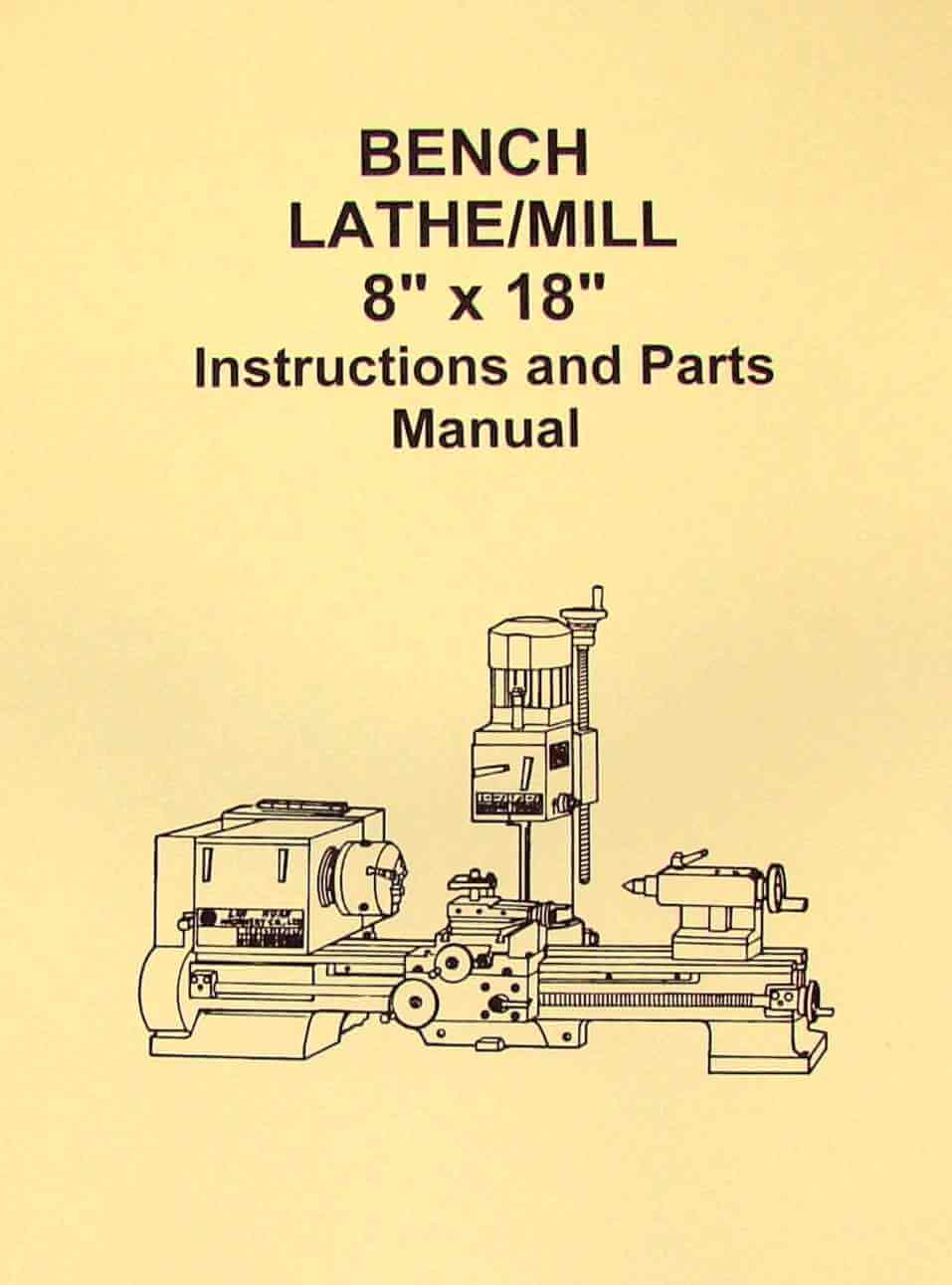

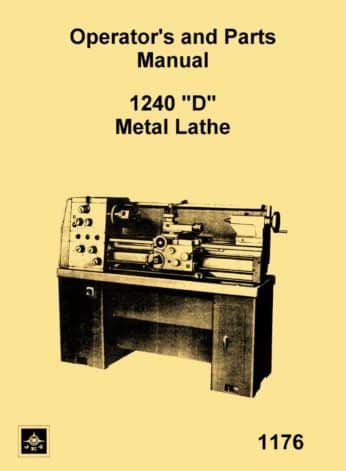

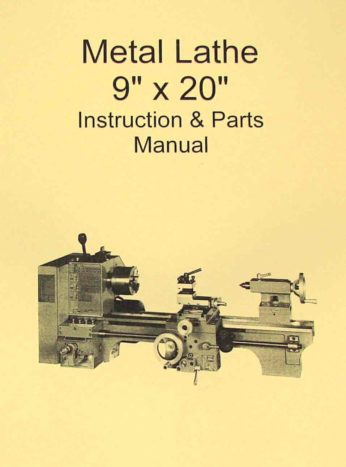

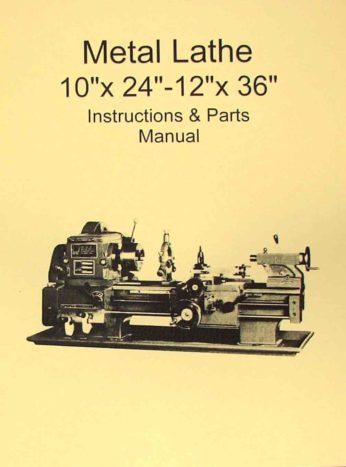

This is a reproduction, not a photocopy, of an original Asian 8″x18″ Bench Lathe/Mill Instructions and Parts Manual. This machine is manufactured in Asia and has been sold under many different names including: JET, Grizzly, Enco, MSC, etc… This manual contains information on lubrication, adjustments, maintenance, and controls as well as a complete parts list with exploded view diagrams.

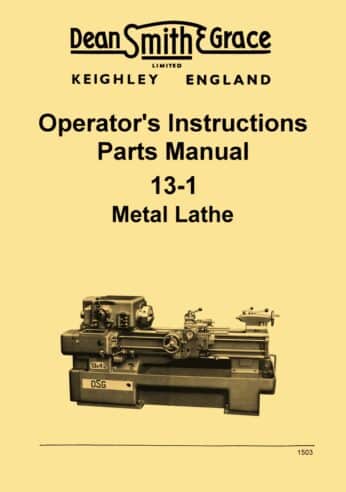

Photo:

|

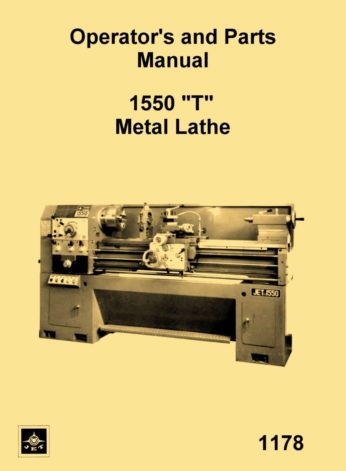

The manual above may help you operate and maintain your metal lathe. If you would like to learn more about metal lathework techniques, the names and proper uses of different lathe tools, and other lathe operations, I would recommend clicking on the pictures of these two books here. We also have a complete series of different machinist books on sharpening, gearmaking, milling machines, and more here: Workshop Machinist Series |

|

|

|---|

Specifications:

|

Centre distance |

17 l/2″ (450 mm) |

|

Centre height |

3 7/8″ (99 mm) |

|

Swing over cross slide |

4 7/8″ (124 mm) |

|

Headstock Spindle nose |

E-M30 DIN 800 |

|

Spindle bore |

25/32″ (20 mm) |

|

For collets to DIN 6341 |

K 20 |

|

Spindle bearing |

Adjustable Precision taper Roller bearing |

|

Spindle speeds |

65-130-265-350 53O-7OO-I4OO 2800 R.P.M. |

|

Leadscrew |

19/32 – 16 T.P.I. 15 dia. x 1.5 mm |

|

Feeds |

with push and pull knob O.OO2″/O.OO47″ (0.05/ 0.12 mm) per Rev. |

|

Thread pitches |

0.4 – 3 mm 8-80 T.P.I. 0.2 – module |

|

Dia of tailstock barrel |

1,023″ (26 mm) |

|

Traverse of barrel |

1,023″ (26 mm) |

|

Morse taper |

No. 2 |

|

Tailstock set-over forwards |

12 mm |

|

backwards |

8 mm |

|

Motor speeds |

1400/2800 R.P.M. |

|

Power |

3/4 – 1 H.P. |

|

Weight |

160 kg |

|

Floor area |

1000 x 40 mm 40″ x 16″ |

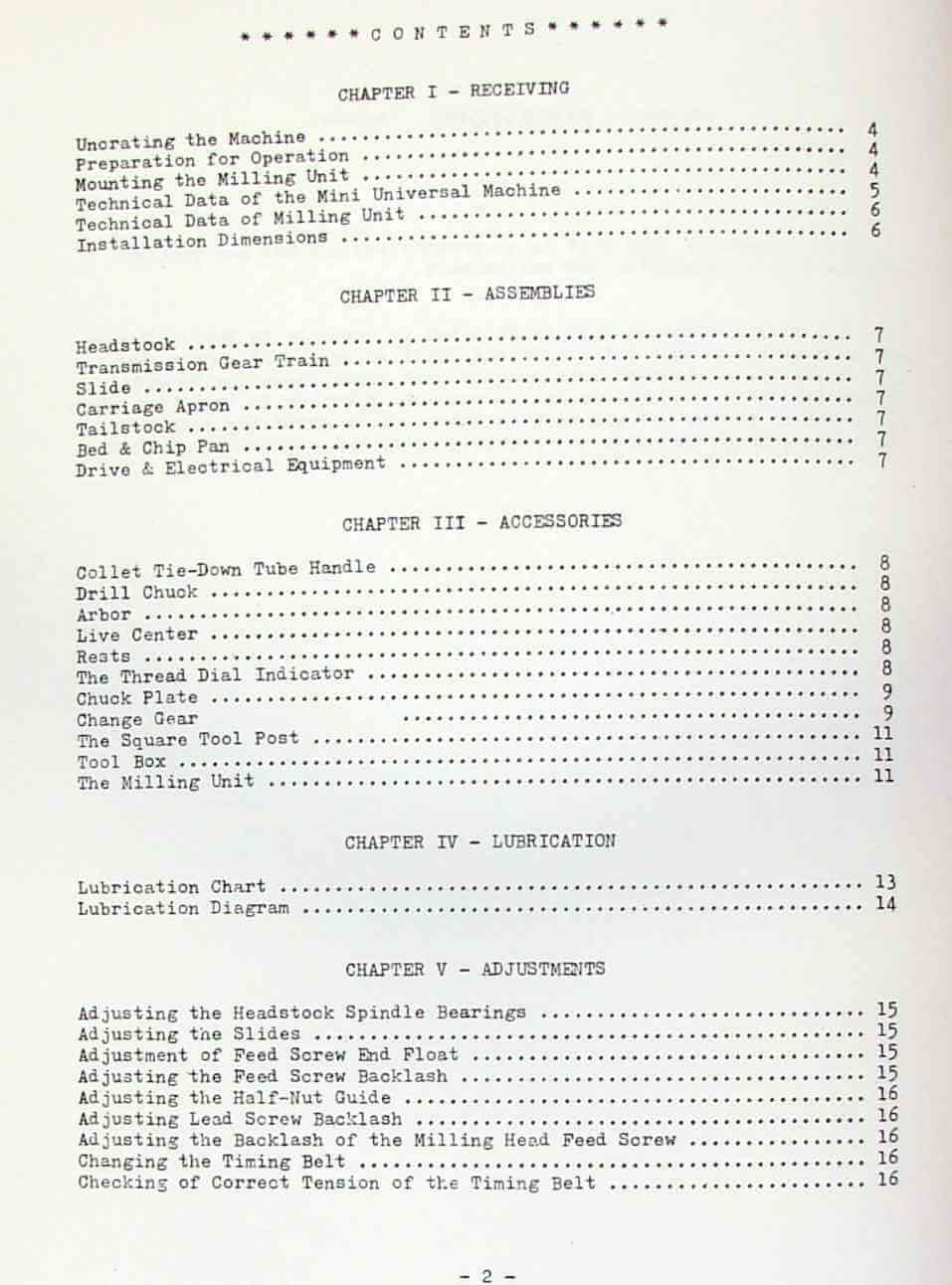

Contents:

|

CHAPTER I – RECEIVING………………………………………………. |

4 |

|

CHAPTER II – ASSEMBLIES…………………………………………… |

7 |

|

CHAPTER III – ACCESSORIES……………………………………….. |

8 |

| Collet Tie-Down Tube Handle…………………………………………….. | 8 |

| Drill Chuck……………………………………………………………………… | 8 |

| Arbor…………………………………………………………………………….. | 8 |

| Live Center……………………………………………………………………… | 8 |

| Rests……………………………………………………………………………… | 8 |

| The Thread Dial Indicator…………………………………………………… | 8 |

| Chuck Plate…………………………………………………………………….. | 9 |

| Change Gear……………………………………………………………………. | 9 |

| The Square Tool Post……………………………………………………….. | 11 |

| Tool Box………………………………………………………………………… | 11 |

| The Milling Unit………………………………………………………………… | 11 |

|

CHAPTER IV – LUBRICATION………………………………………. |

13 |

|

CHAPTER V – ADJUSTMENTS………………………………………. |

15 |

| Adjusting the Headstock Spindle Bearings…………………………….. | 15 |

| Adjusting the Slides…………………………………………………………… | 15 |

| Adjustment of Peed Screw End Float…………………………………… | 15 |

| Adjusting the Peed Screw Backlash……………………………………… | 15 |

| Adjusting the Half-Nut Guide……………………………………………… | 16 |

| Adjusting Lead Screw Backlash………………………………………….. | 16 |

| Adjusting the Backlash of the Milling Head Feed Screw…………… | 16 |

| Changing the Timing Belt……………………………………………………. | 16 |

| Checking of Correct Tension of the Timing Belt……………………… | 16 |

| CHAPTER VI – ELECTRICAL DIAGRAMS………………………. | 18 |

| CHAPTER VII – PARTS DIAGRAMS……………………………….. | 21 |

Overview:

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear.