We had one of our readers that wanted to learn more about his great 13″ x 6′ South Bend metal lathe. These South Bend lathes are beautiful machines They were built like tanks. As long as you install them properly, keep them clean, keep them trim, and oil the lathe properly they should last forever.

The serial number of his lathe was No. 50328 and the catalog number was stamped 1866-C as you can see in the picture below. This information dates his lathe around 1931. The reader wanted some clarification as to if the 1866-C was misstamped, because most of the information and advertisements with a similar machine show the catalog number as 166-C.

The 1866-C is a real and correct catalog number for your lathe. The difference between the 1866-C and the 166-C is the 1866-C was considered a “Tool Room Precision Lathe”, which came with various attachments like the collet attachment, taper attachment, threading dial, etc…

This particular South Bend lathe is part of the “N” series, which is distinguished mainly by the design of the apron. The “N” series wasn’t in production for very long. South Bend started producing them around 1930. It was replaced by the “R” series after 1934, and that is what South Bend used to the end. They sold the “N” until about 1937. There is always a lot of overlap with South Bend on some of their parts.

Here are some pictures of the South Bend Lathe after it has been cleaned some.

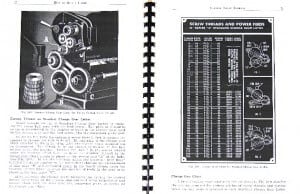

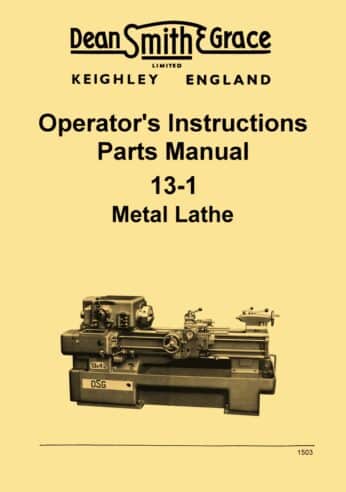

Manuals for South Bend 13″ x 6′ Metal Lathe Catalog No.1866-C

We have a few manuals that cover this South Bend 13″ x 6′ Metal Lathe Catalog No.1866-C. We have new revised parts manual that shows the main parts of the lathe here:

| Submit Your Machine |

| Do you want to know more about your machine?

Email us your details with pictures, and we’ll put together the best information we can find. Plus, we can get other readers’ input to help you learn more. Also, feel free to email us if you want us to share your machine on our site. Email your information to: info@ozarkwoodworker.com |