Description

Number of Pages: 40

This is a reproduction, not a photocopy, of an original Unimat Miniature Machine Techniques Handbook and Operator’s Manual. This manual is for the Unimat Model DB 200 pictured below.

Contents:

Abrasives………………………………, 31, 32, 33

Adjustable hand tool rest………………………., 30

Advanced techniques…………………………, 34, 35

Back-plate adaptors……………………………., 18

Boring……………………………………….., 10

Buffing………………………………………., 32

Center punching, 8; centering……………………., 8

Chucks, centering, 18; collets, 23; drill…….., 2, 21;

3-jaw, 2, 6, 7; 4-jaw, 18; reversing jaws, 6; special,

12; truing (mounting)………………………….., 18

Circular saw, attachment, 27, 28; speeds…………., 39

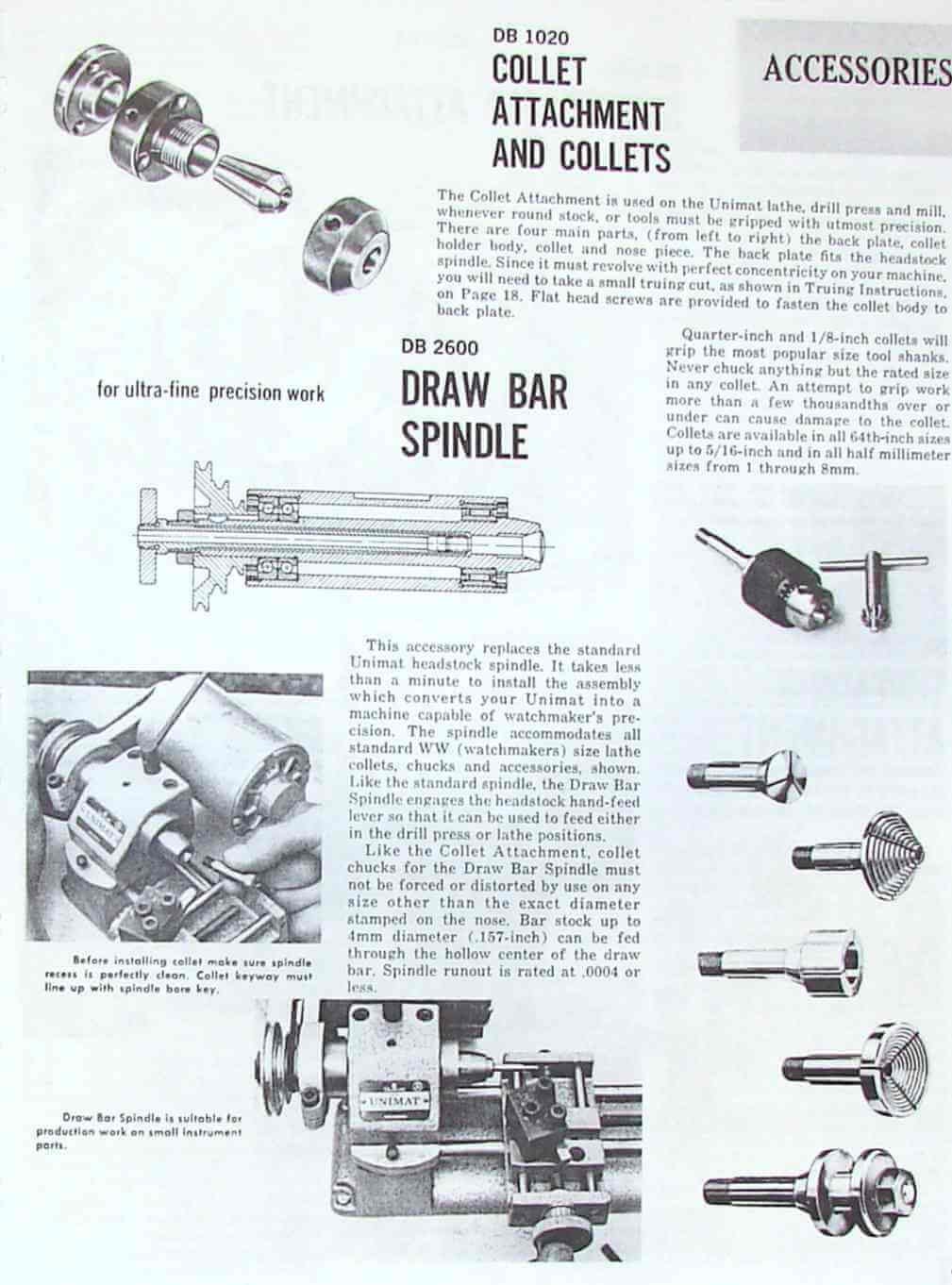

Collet attachment, 23, truing (mounting), 18; collets, 23

Customer service department………………………, 5

Cutting speeds…………………………………, 39

Defective parts…………………………………, 5

Dies…………………………………………., 33

Dividing……………………………, 21, 22, 34, 35

Dressing grinding wheels……………………….., 33

Drilling, angle, 14; centering, 15; deep hole……., 13;

hand, 4, 16; miniature hole, 10, 14; speeds………, 39;

techniques, 10, 13; vertical………………….,10, 12

Draw-bar spindle………………………………., 23

Facing…………………………………., 8, 12, 18

Finishing techniques (see abrasives, buffing, grinding, polishing,

sanding, wood turning)

Flexible shaft, 31 (see buffing, drilling, polishing, sanding)

Foot switch……………………………….., 26, 36

Gear cutting……………………………., 4, 21, 22

Grinding, angle, 16; bench, 15-17; guard, 32; safety,

32; speeds, 16, 39; surface, 4, 16; tool…………., 16

Guarantee…………………………………….., 33

Headstock, alignment, 10; maintenance, 33; raising block, 2, 28-30

Indexing…………………………………, 4, 20-22

Jaws, reversing chuck jaws………………………., 6

Jig saw attachment, 3, 26; speeds……………….., 39

Machine, adjustments, 8, 9; vise…………….., 19, 29

Maintenance, bed-ways, 9, 15; lathe parts, 33; live center, 30; spindle……………………………., 33

Mandrels, 11; turning………………………….., 11

Measuring accessories………………………….., 36

Milling, 2, 19, 20; speeds, 39; table………, 2, 19, 20

Motor speeds…………………………………..,39,

Parts, replacement list…………………….., 37, 38

Polishing arbor, 3, 32; preparations,32, (see abrasives, buffing)

Pulley setups…………………………………., 39

Power feed attachment………………………….., 17

Reaming………………………………………., 11

Roughing………………………………………, 32

Rubber backing pad…………………………….., 32

Safety, 16, 32, 33; goggles…………………….., 36

Sanding, abrasive, 32; disc, 29; cement………….., 29

Saber saw blades………………………………., 26

Sawing, circular, 27, 28; jig, 3, 26; speeds…….., 39; machine………………………………………., 29

Scribing………………………………………., 8

Slow speed attachment……………………, 24, 25, 39

Speed chart……………………………………, 39

Spur drive center………………………….., 29, 30

Steady, for wood, 30, rest………………………, 31

Taper turning…………………………………., 11

Tapping, 12; taps………………………………, 33

Threading, attachment, 4, 24, 25; charts…………, 25;

die, 33; patterns, 4, 24; speeds, 39; tap…………, 12

Tips…………………………………………., 33

Truing instructions……………………………., 18

Truing diamond…………………………………, 32

Tools, cutting, 8, 9; sharpening…………….., 4, 16;

Turning, 2; faceplate, 12; metal, 7; speeds………, 39;

turning to size, 9; wood turning………………, 31-33

Watchmaker’s spindle……………………………,23,

Wire brushes……………………………….., 31-33

Wood turning, 29-33; chisels, 29-30; finishing……., 30

Work holding methods……………………………, 14

Overview:

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear.