Description

Number of Pages: 68, printed 5.5″ x 8.5″

This is a reproduction, not a photocopy, of an original The ABC’s of Internal Grinding Manual a handbook for Operators of Internal Grinding Machines. This handbook goes into a lot of the details of internal grinding as you can see in the contents listed below the pictures. This is a great book to learn how to do internal grinding properly

Preface:

This booklet is intended primarily for operators of Internal Grinding Machines. It endeavors to answer some of the very practical questions which you and your fellow grinder hands have been asking, such as, how to select the proper wheel for different internal grinding jobs and how to correct common grinding faultsa knowledge of which will help you to become a more valuable operator.

Contents:

Know your grinding machine and How to set it up for each job……5

Mount the work correctly……………………………………5

Be sure work has been machined to specifications……………..11

Select proper style and size of spindle nose or quill…………15

Mount the wheel carefully on the spindle…………………….18

Check wheel speed and direction of rotation………………….19

Start with work speed of 150 to 200 s.f.p.m………………….20

True new wheel before starting to grind……………………..21

Adjust grinding stroke to length of hole…………………….23

Set traverse speeds and feeds………………………………25

Wherever possible, grind wet……………………………….27

Test grind one piece for straightness……………………….28

Rough grind ……………………………………………..29

Finish grind……………………………………………..29

Internal centerless grinding……………………………….30

The centerless principle ………………………………….30

On-center and off-center arrangements……………………….31

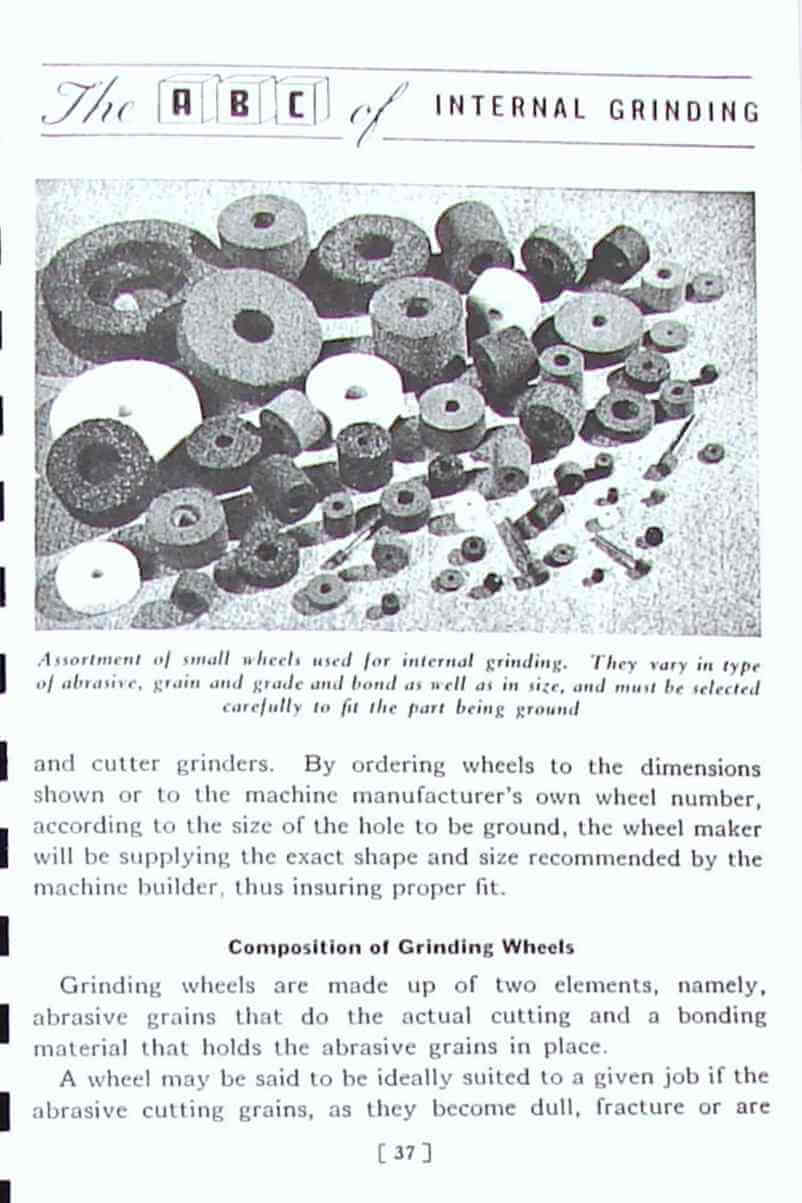

Select the proper grinding wheel for each job………………..36

Composition of grinding wheels……………………………..37

The Abrasives…………………………………………….38

The Bonds ……………………………………………….38

Structure (grain spacing)………………………………….39

Norton method of marking grinding wheels…………………….41

How a grinding wheel cuts………………………………….42

Factors affecting the selection of wheels……………………43

Material to be ground……………………………………..44

Amount of stock to be removed, accuracy and finish required……45

Area of contact between wheel and work………………………45

Relation between wheel and work speeds………………………46

Rigidity of wheel spindle and condition of grinding machine……47

Wheel recommendations for specific jobs……………………..47

Be able to recognize common grinding troubles and correct them…49

Plug Gages-Their Care and Use………………………………60

Recommended sizes of wheels for internal grinding…………….64

Suggested stock to be left for internal grinding……………..66

Table of Grinding Wheel Speeds……………………………..68

Overview

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear; they are then comb bound with heavy cover pages so they lie flat on the workbench.