Description

Number of Pages: 47

This is a reproduction, not a photocopy, of an original Clausing Operating Instructions and Parts List for 12-Inch Variable Speed Lathe 5900-Series Manual that covers serial numbers 5002000 to 502099. This manual covers the older version of this series, and was a lot more difficult to come across. It contains information on setup, lubrication, maintenance, and controls as well as a complete parts list and exploded views and adjustments. Please read the index below.

We have a manual for the accessories and attachments available for the Clausing 12″ 5900 lathes here:

Note: This manual covers the following model numbers:

5902 5903 5904 5907* 5908* 5909*

5912 5913 5914 5917* 5918* 5919*

*These machines just don’t have the clutch and brake

Please Note: There are two majorly different versions of 5900 series of lathes.

We carry two different manuals for the 5900 series of Clausing lathes, because they made a significant change to the motor and speed control system among other things. This manual covers lathes with serial numbers 5002000 to 502099. The difference between the two systems is very apparent as you can see from the pictures below.

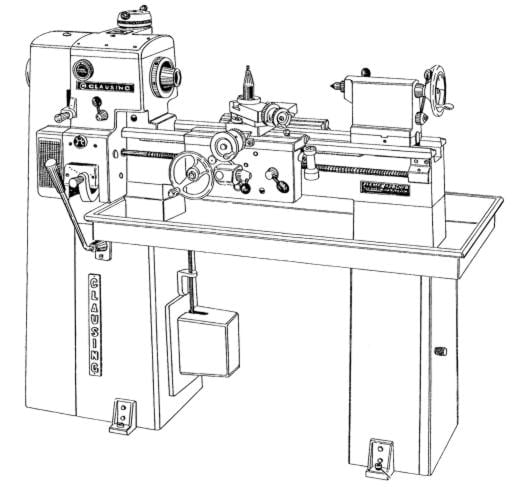

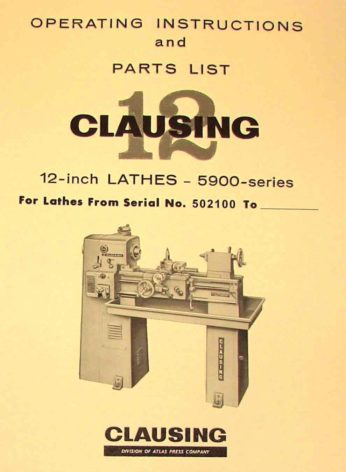

This manual cover this style of 5900 lathe with serial numbers between 5002000 to 502099

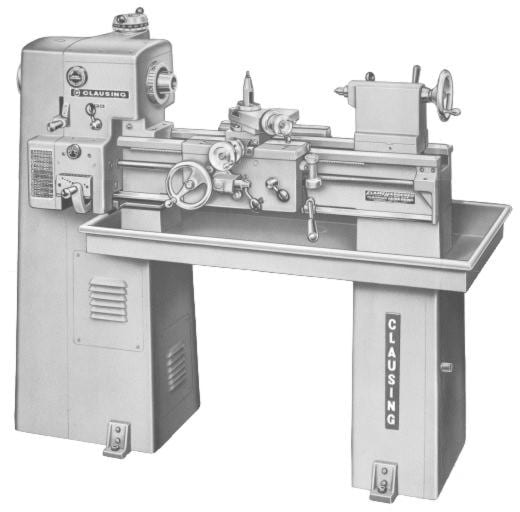

This is the newer style of the 5900 series lathe at serial number 502100 and higher.

We have the manual for this style of lathe here:

CLAUSING 12″ 5900 Series Variable SPD Metal Lathe Instruction & Part Manual Above 502100

Contents

INSTALLATION Dimension Drawing.......................................2.1 Foundation..............................................3.1 Cleaning................................................3.1 Moving and Lifting......................................3.1 Electrical Connections..................................4.1 Anchoring...............................................4.1 Leveling................................................4.1 LUBRICATION Lubrication Chart.........................................5 OPERATION Functional Diagram........................................6 Back Gear Controls......................................7.1 Spindle Speeds..........................................7.1 Headstock...............................................8.1 Quick-Change Gear Box...................................8.1 Carriage............................................8.1 & 9 Tool Holders.............................................10 Tailstock................................................11 Chucks and Face Plates...................................11 MAINTENANCE AND ADJUSTMENTS Preventive Maintenance.................................12.1 Clutch Adjustment......................................12.1 Carriage Bearing Plates................................12.1 Gibs...................................................12.1 Countershaft Pulley Alignment..........................12.1 Shear Pin................................................13 Spindle Bearings.........................................13 Variable Belt...................................14.1 & 15.1 Timing Belt............................................15.1 Upper Variable Control Cylinder..........................16 Lower Variable Control Cylinder..........................16 PARTS INDEX & INSTRUCTIONS FOR ORDERING PARTS......17.10-34 ATTACHMENTS..............................................35 TABLES....................................................i

Overview

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page,and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear; they are then comb bound with heavy cover pages so they lie flat on the workbench.