People often ask us how to measure the size and swing of their wood or metal lathe. Lathes are generally described by the maximum size of material that can be cut or machined on the lathe. Before machining a workpiece, the following measurements must be considered: the diameter of the work that will swing over the bed and the length between lathe centers. Often you will see numbers like 14×40 or 9×42 describing the size of a lathe. So what do these numbers mean?

How to Measure the Lathe Swing and Size

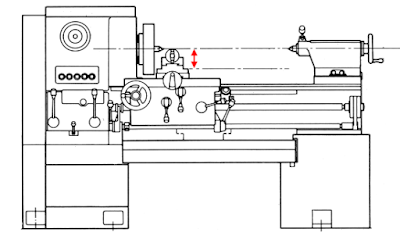

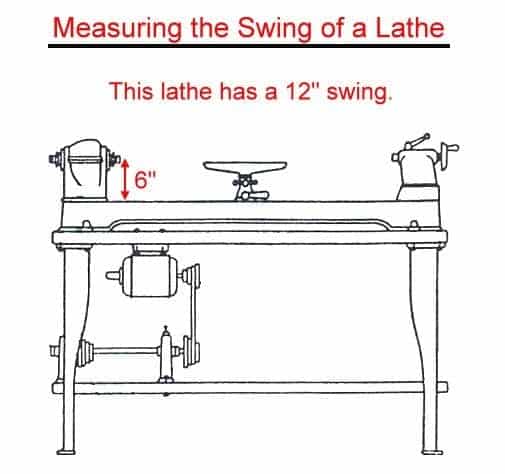

What does the term “swing” on a lathe mean? The first number is referred to as the swing of the lathe which is the maximum diameter of a piece or work that can fit in the lathe. If you have a lathe and want to measure for the swing, you simply measure from the bed of the lathe to the center of the spindle, and then double that measurement. If you measure 6″, then you have a 12″ swing lathe.

- Special Note: Sometimes there can be some discrepancies between the actual measured swing and the swing the manufactures label the machine as being. I’ve only seen this on larger geared head metal lathes and European metal lathes. Some foreign lathes were made on metric standards, and they rounded to the nearest US standard size. Some companies labeled them based on the measurement from the top of the cross-slide for the tool holder on the metal lathe to the spindle. For example this Bradford Metalmaster geared head metal lathe series had actual measured swings of 14.5″, 16.5″, and 18.5″, but Bradford labeled the lathes as 12″, 14, and 16″.

Keep in Mind

On metal lathes, it is important to know the swing over the carriage where your tool holder sits. A lot of companies will give you this specification, and some companies in the past have used this measurement as the size of the “actual” swing of the lathe. It is obvious, if you have to cut something over the carriage of the lathe, it will make your working swing smaller in diameter.

How to Measure Distance Between Centers on a Lathe

The second number in the sequence 14x40 is referred to as the distance between centers. This is the distance between a center in the headstock to a center in the tailstock. This gives you an idea as to how long the working area of the lathe is. However, a lot of companies in the 40’s or before used the size of the bed as the second number.

Depending on what tooling and what kind of cuts, drills, bores, etc… you are trying to use can vary the maximum length of material you can work on in your lathe.

A 10×24 lathe can handle work that has a diameter up to 10″ and a length between centers of 24.”