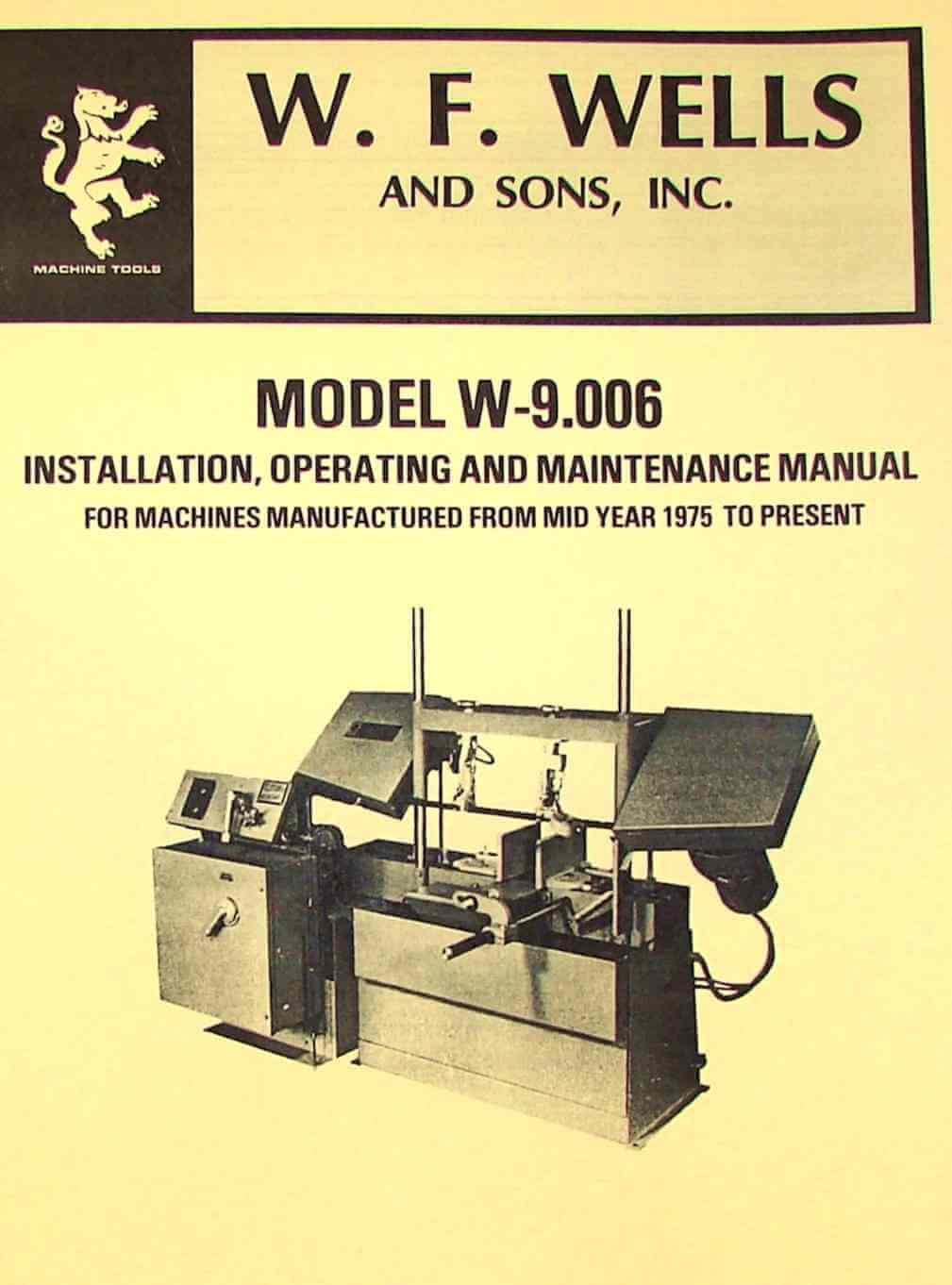

This is a reproduction, not a photocopy, of an original W.F. Wells Model w-9.006 Horizontal Band Saw Instructions and Parts Manual. This manual contains general safety instructions, operation instructions, adjustments, maintenance, lubrication, and a complete set of exploded view part diagrams with descriptions. See index below

SAFETY MANUAL

A. OSHA and the metal cutting band saw machine……………..2

B. Safety during installation…………………………….2

C. Safety during manual operation…………………………2

D. Safety during automatic operation………………………3

E. Safety during maintenance……………………………..3

INSTALLATION, OPERATING AND MAINTENANCE MANUAL

1. INTRODUCTION………………………………………….2

2. INSTALLATION………………………………………….2

B. Electrical hookup……………………………………..2

C. Check-out…………………………………………….2

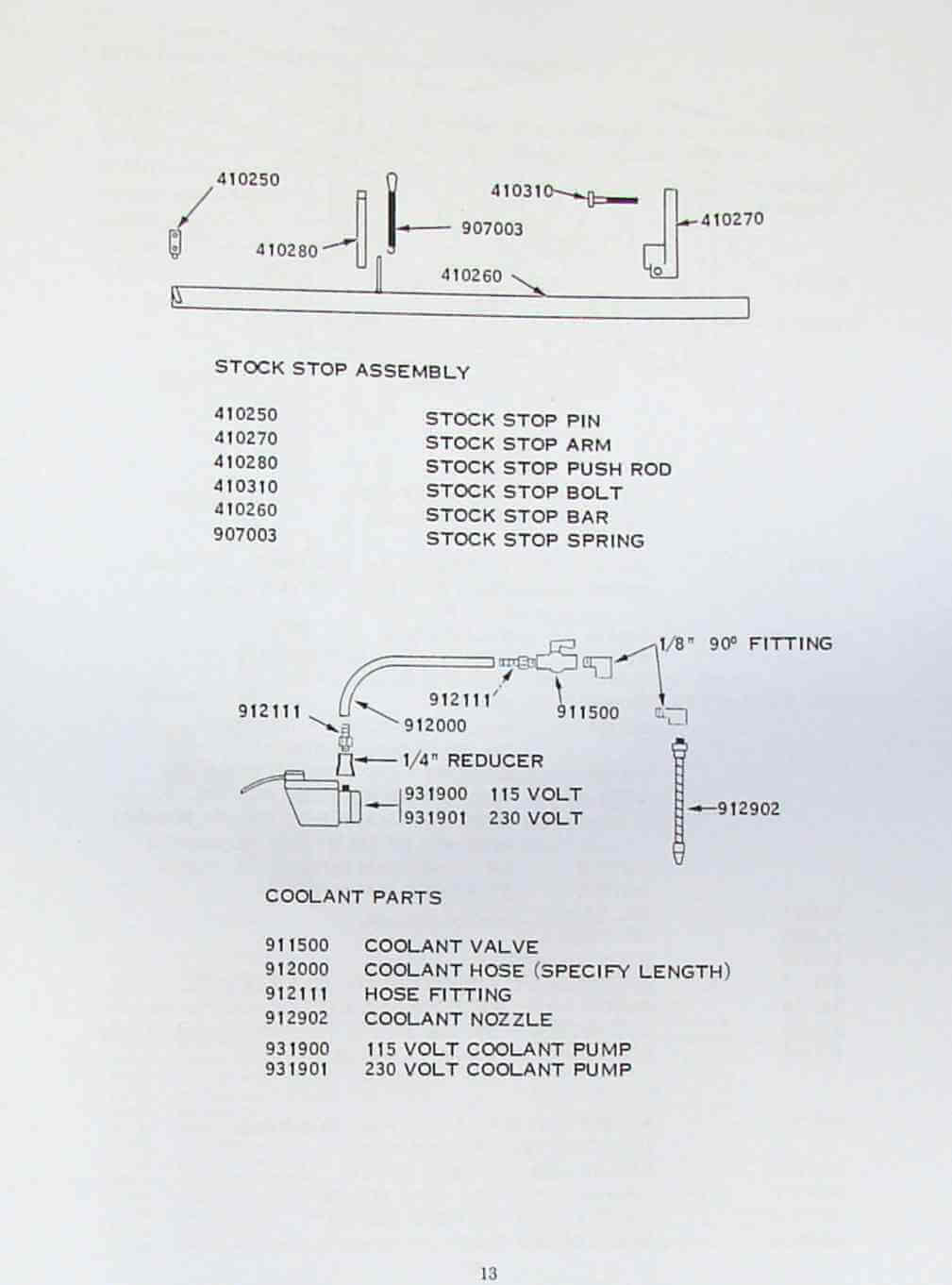

D. Stock stop installation………………………………..2

E. Blade installation…………………………………….2

3. OPERATION…………………………………………….2

A. Cutting Force…………………………………………2

B. Blade speed…………………………………………..4

C. Vise operation………………………………………..4

D. Stock stop bar………………………………………..4

E. Guide arm setting……………………………………..4

F. Cutting head descent rate………………………………5

G. Coolant………………………………………………5

H. Angle cutting…………………………………………5

4. MAINTENANCE…………………………………………..5

A. Lubrication…………………………………………..5

B. Blade wheel alignment………………………………….6

C. Ring gear & pinion adjustment…………………………..6

D. Timing belt adjustment…………………………………6

E. Blade guide adjustment…………………………………6

F. Blade brush adjustment…………………………………6

G. Blade tension indicator accessory……………………….6

H. Frame thrust screw adjustment…………………………..7

5. TROUBLE SHOOTING………………………………………7

A. Crooked cuts………………………………………….7

B. Blade stalls………………………………………….7

C. Broken blades…………………………………………7

D. Stripped teeth………………………………………..7

6. SPARE PARTS FORMINIMUM DOWNTIME…………………………8

7. REPLACEMENT PARTS LIST…………………………………8

SERIES I CONTROL CONSOLE 3RD EDITION Operating and Parts Manual

1. OPERATING INSTRUCTIONS………………………………..2

A. Electrical controls…………………………………..2

B. Hydraulic controls……………………………………2

C. Preventive Maintenance………………………………..2

2. CUTTING HEAD RETURN LIMIT SWITCH ADJUSTMENT……………..3

A. Models W-9 and F-15…………………………………..3

B. Models B-25 and G-30………………………………….3

C. Limit Switch Adjustment……………………………….3

3A.CUTTING HEAD RETURN COLLAR ADJUSTMENT, Models B-25 and G-30.4

3B.CUTTING HEAD RETURN COLLAR ADJUSTMENT, Models W-9 and F-15..4

4. SPARE PARTS FOR MINIMUM DOWNTIME……………………….5

5. PARTS LIST…………………………………………..6

BAND SAW BLADE SELECTION AND APPLICATION

General…………………………………………………..2

Blade Types……………………………………………….2

Carbon Steel Blades Hard Edge, Flexible………………………2

Back Blades……………………………………………….2

Hard Back Blades…………………………………………..2

Alloy Steel Blades…………………………………………2

High Speed Steel Blades…………………………………….2

Super High Speed Blades…………………………………….3

Carbide Tipped Blades………………………………………3

Carbide Edge Coated Blades………………………………….5

What Blade Should I Use?……………………………………5

Blade Pitch Selection………………………………………5

Blade Set Selection………………………………………..5

Blade Tooth Form Selection………………………………….5

Coolant…………………………………………………..5

Cutting Force……………………………………………..5

Blade Speed……………………………………………….7

Accuracy of Cut……………………………………………7

Production Cutting…………………………………………7

Cost Per Cut………………………………………………8

Blade Speed Chart…………………………………………10

Cutting Rate Calculation…………………………………..11

Sawing Problems…………………………………………..13