Description

Number of Pages: 70

This is a reproduction, not a photocopy, of an original Sheet Metal Work Handbook. What I like about this book is it contains information for someone with a small shop with medium size machines or someone without any machines at all. This book contains information on how to measure and layout the metal to achieve certain shapes and forms. It discusses how to use benders, brakes, forming rollers, burring machines, beading machines, and other had powered machines. It also contains a good chapter on soldering different metals and how to connect different types of joints. Please read the contents below for more information.

I like this book, because it has given me lots of tips for techniques that I’ve used on the job or in my shop over the years. This would be useful for anyone building or repairing houses, or building specialty boxes or covers.

Contents:

Unit 1. Safety……………………………………9

Unit 2. Metals Commonly Used in Sheet Metal Work…….10

Unit 3. How to Make Simple Layouts…………………23

Unit 4. How to Lay Out and Develop Patterns

for Cylindrical, Conical, and Transition Parts………26

Unit 5. How to Cut Sheet Metal…………………….31

Unit 6. How to Cut Sheet Metal With a Ring and Circle

Shears………………………………………….33

Unit 7. Stakes Used in Forming Sheet Metal………….35

Unit 8. How to Bend Sheet Metal Hand Process………36

Unit 9. How to Make a Hem by the Hand Process……….38

Unit 10. How to Fold an Edge With a Bar Folder or a Pan

Brake…………………………………………..39

Unit 11. How to Make a Wired Edge Hand Process…….42

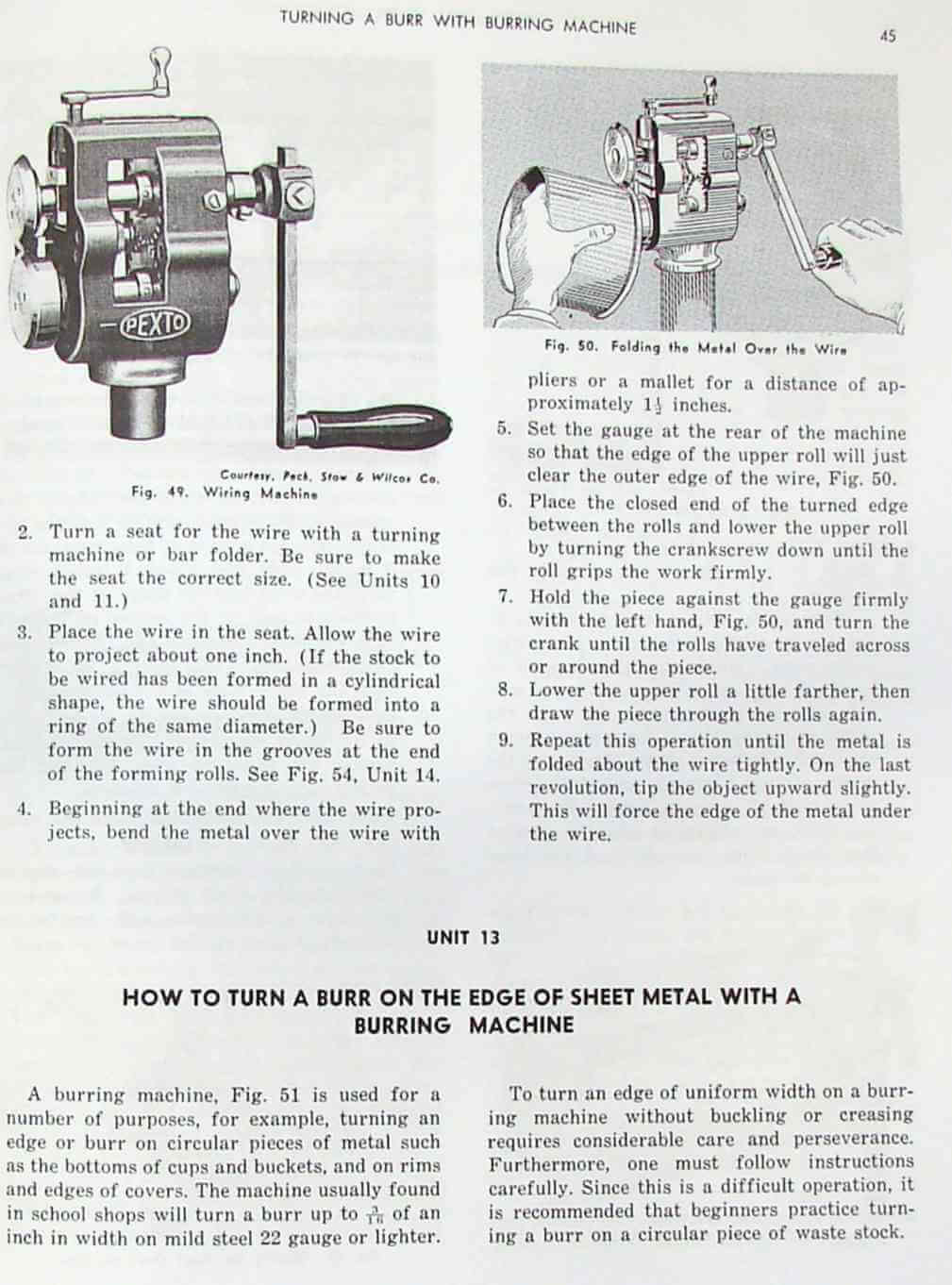

Unit 12. How to Make a Wired Edge Machine Process….43

Unit 13. How to Turn a Burr on the Edge of Sheet Metal

With a Burring Machine……………………………45

Unit 14. How to Form Sheet Metal With Forming Rolls….47

Unit 15. How to Form a Bead With a Beading Machine…..48

Unit 16. Maintenance and Adjustment of Sheet Metal

Equipment……………………………………….49

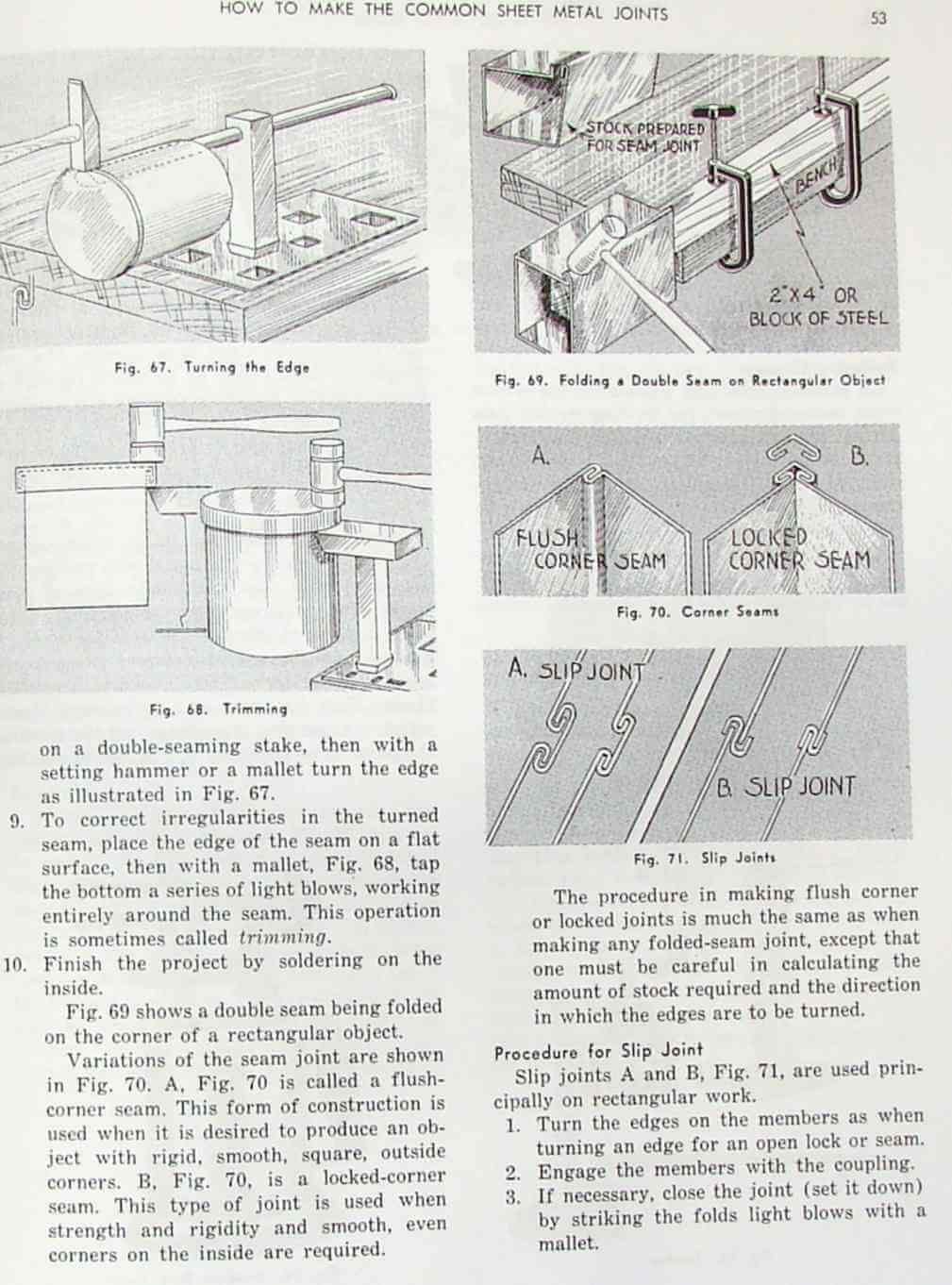

Unit 17. How to Make the Common Sheet Metal Joints…..50

Unit 18. Soldering Devices and Appliances…………..54

Unit 19. Fluxes and Solders……………………….56

Unit 20. How to Tin a Soldering Copper……………..57

Unit 21. How to Make a Soldered Joint………………58

Unit 22. How to Sweat Solder a Lap Joint……………61

Useful Tables and Formulae………………………..63

Projects………………………………………..67

Reference List…………………………………..73

Index…………………………………………..75