Description

Number of Pages: 59, printed 5.5″ x 8.5″

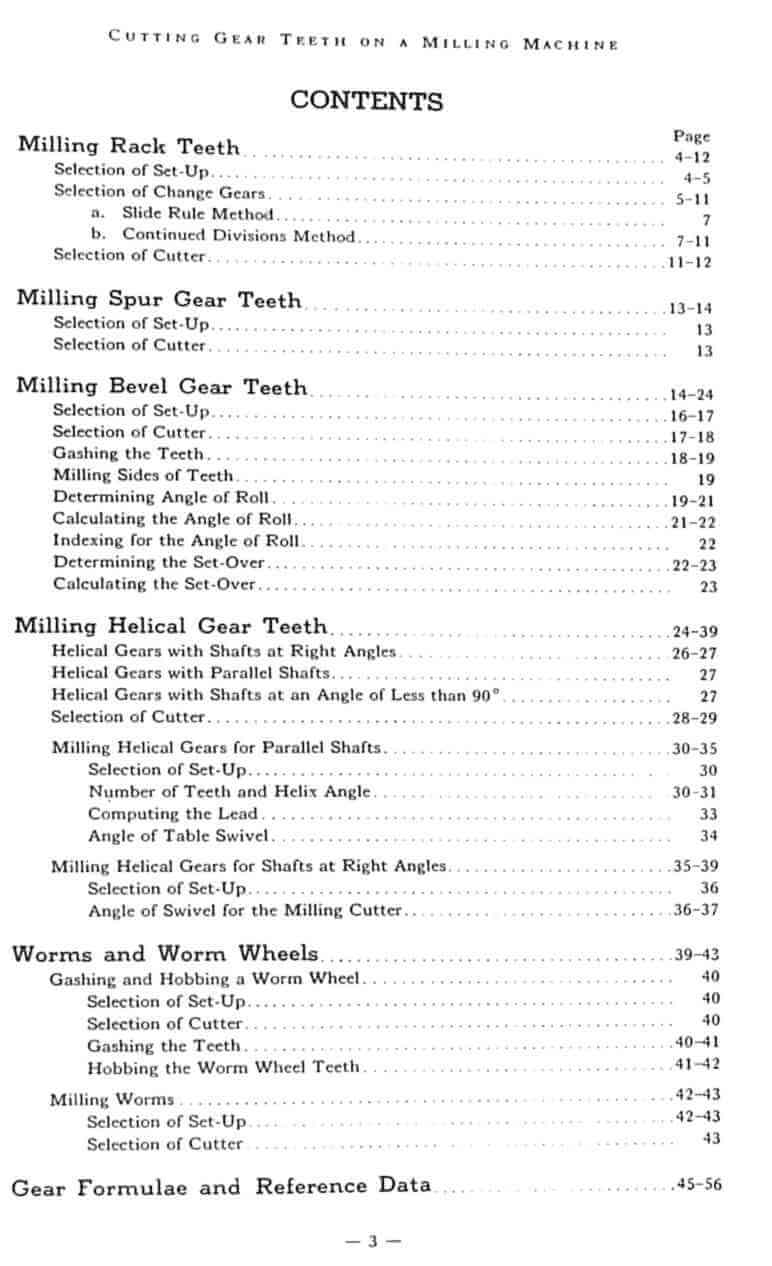

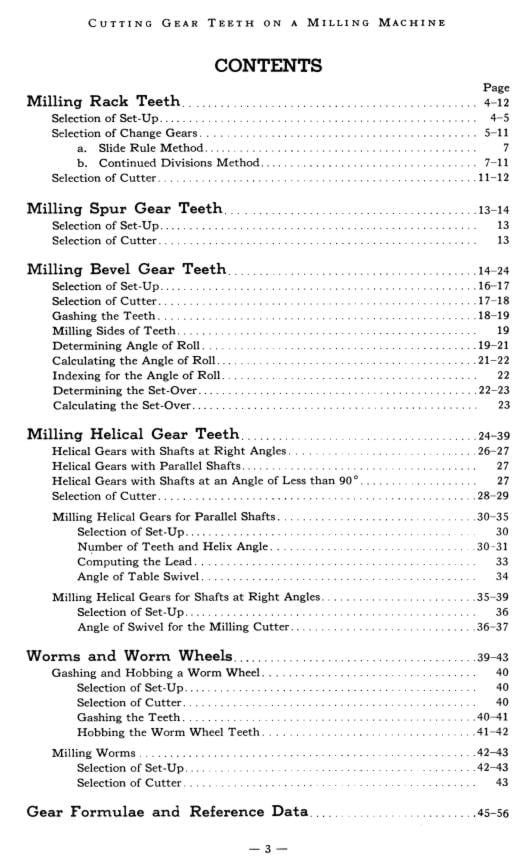

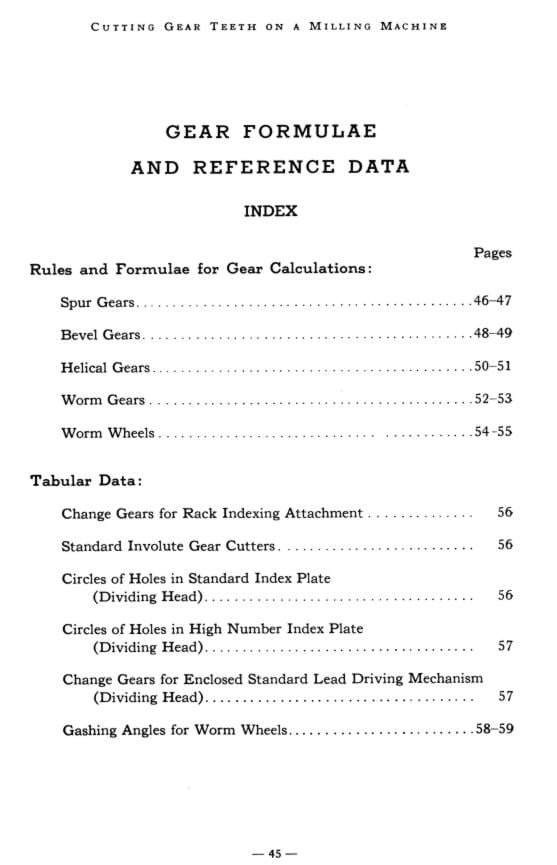

This is a reproduction, not a photocopy, of an original Cincinnati Cutting Gear Teeth on a Milling Machine book. This book provides information on the formulas, cutter selection and set up to for milling rack teeth, spur gear teeth, bevel gear teeth, helical gear teeth, worms, and worm wheels. Please see pictures of index below.

This is one of my favorite books on cutting gears. It is simple and gets right to the point. It gives you critical information in the right areas so you don’t have to hunt and peck through the text.

For rack gears it describes the slide rule and continued division method. When milling spur gears it provides the formula, and describes examples on how to cut the teeth. It shows how to set up a bevel gear on a dividing head, and describes which operations should be performed first with the formulas on how to calculate them. It provides information about how to calculate the angle of row and determining the set-over. There is a lot more information on helical gears, and it covers both helical gears for parallel shafts and helical gears for shafts at right angles. Finally for worm gears, it explains how to gash and hob the worm teeth, and how to mill the worms.

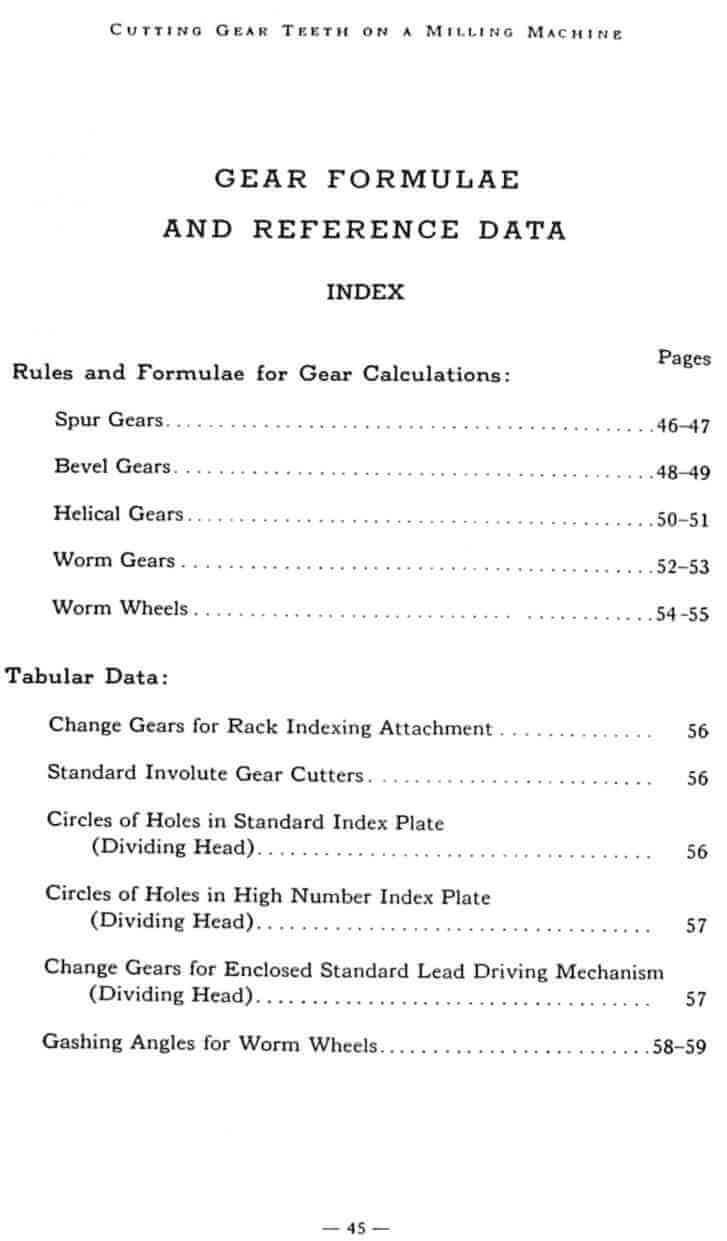

In the back is a list of formulas and calculations for the different types gears as well as tables for indexing plates used on dividing heads. If you are interested in milling gears, this is one of the best books I’ve seen on providing information that gets right to the point.