Description

Number of Pages: 94

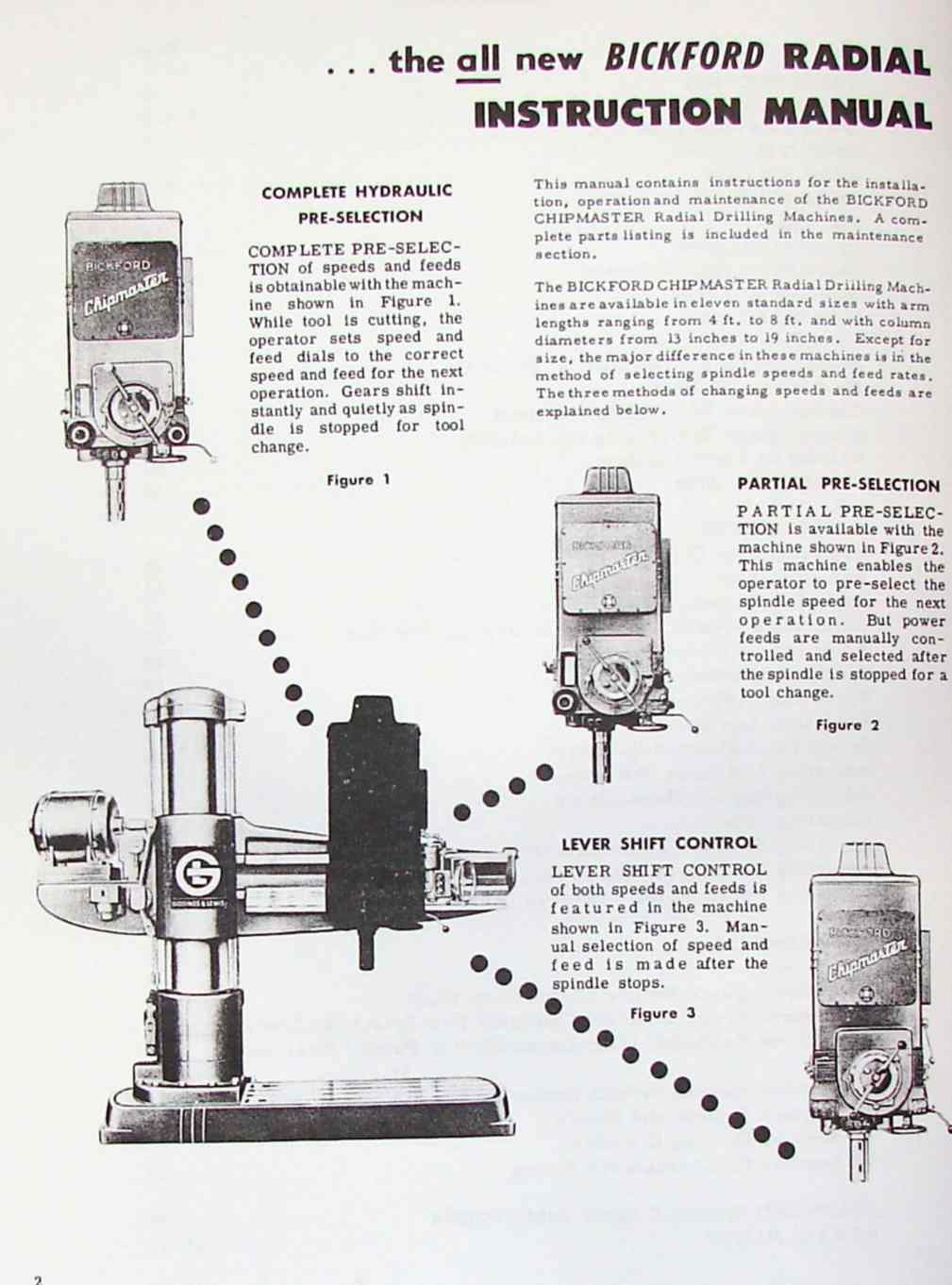

This is a reproduction, not a photocopy, of an original Gidding & Lewis Bickford Chipmaster 13″, 15″, 17″, 19″ Radial Drill Operation and Parts Manual which covers the model 954 and more. This manuals covers the Complete Hydraulic Pre-Selection, Partial Pre-Selection, and Lever Shift Controlled heads. It contains information on lubrication, maintenance, and controls as well as a complete parts list and exploded views and adjustments. Please read contents below.

Click Picture to Enlarge

ContentsINTRODUCTION........................................................2

INSTALLATION....................................................3,4,5

PREPARATION FOR USE.................................................6

SPECIFICATIONS......................................................7

LUBRICATION.......................................................8/9

OPERATION

Starting...........................................................11

Spindle Operation..................................................12

Selection of Spindle Speeds.....................................12,13

Selection of Feeds..............................................13,14

Fine Hand Feed.....................................................14

Hand Feed Operation................................................14

Setting the Compensating Dial Depth Gage...........................14

Positioning the Head...............................................15

Clamping and Unclamping the Head...................................15

Clamping and Unclamping the Column.................................15

Raising or Lowering Arm............................................15

Clamping the Arm...................................................15

ADJUSTMENTS

Adjusting Arm Clamp................................................16

Adjusting Arm Lubrication..........................................16

Adjusting Column Clamp.............................................17

Adjusting Forward and Reverse Driving Clutches.....................17

Adjusting Quick-Return Clutch......................................18

Spindle Adjustment.................................................18

Speed Dial Alignment...............................................19

Feed Dial Alignment................................................19

Safety Feed Clutch Adjustment......................................19

Adjusting Hydraulic Head Clamp.....................................19

Adjusting Manual Head Clamp........................................20

Adjusting Gibs.....................................................20

Adjusting Spindle Counterbalance...................................21

Adjusting Lubricating Oil Pressure.................................21

Adjusting Power Rapid Traverse Clutch..............................21

DISASSEMBLY

Taper Pins.........................................................21

To Remove Quick-Return Clutch from Head............................22

To Remove Feed Unit from Complete Pre-Select Machines..............22

To Remove Feed Unit from Lever-Shift & Partial Pre-Select Machines.22

To Remove Spindle without Removing Spindle Sleeve..................23

To Remove Spindle and Sleeve.......................................23

To Remove Driving Clutches.........................................23

To Remove Counterbalance Spring....................................24

STANDARD SPINDLE NOSE DIMENSIONS...................................25

REPAIR PARTS....................................................26-91