Description

Number of Pages: 39

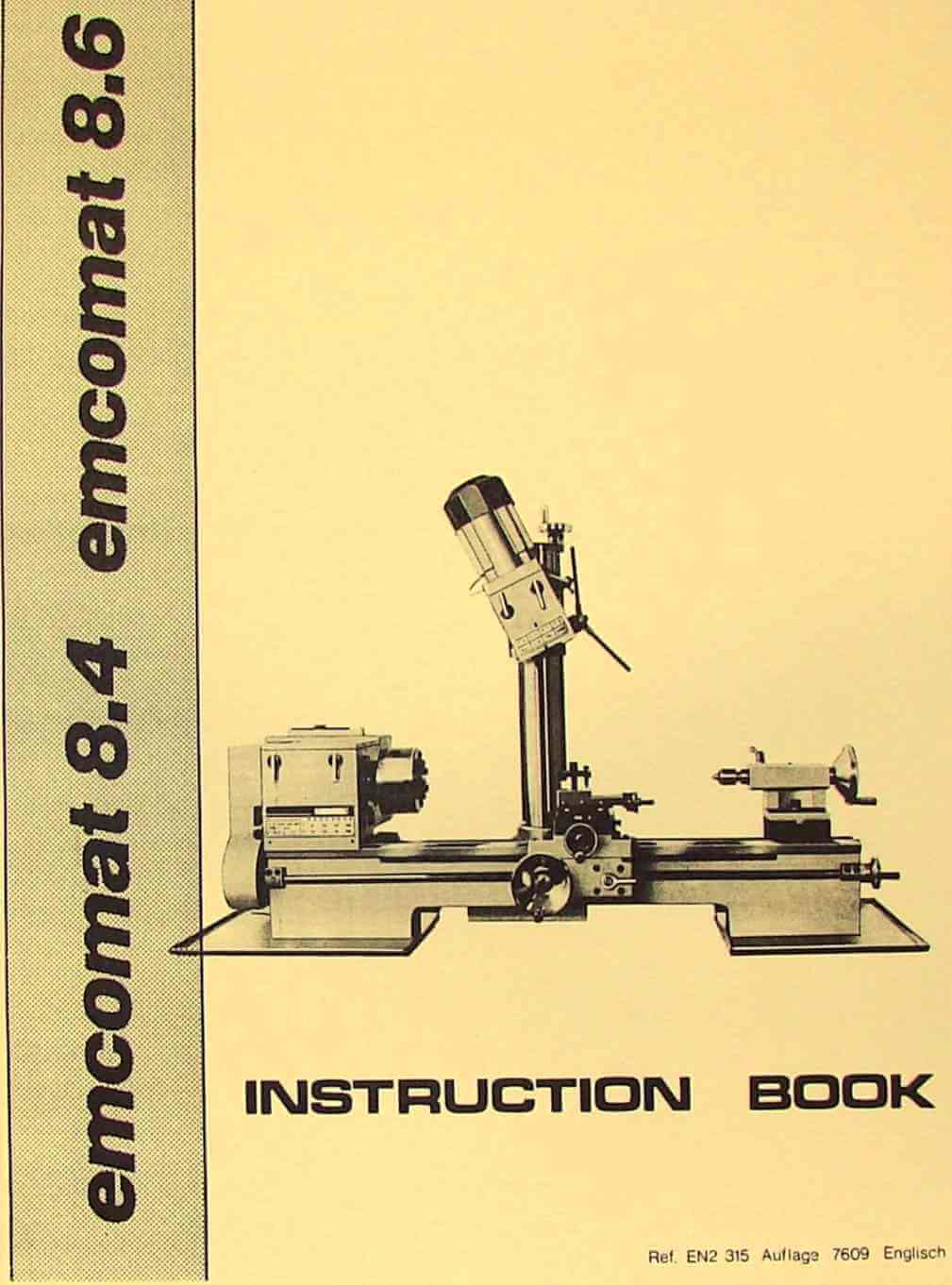

This is a reproduction of an original Emco Emcomat 8.4 and 8.6 Lathe with milling attachment Instructions Manual.. This manual contains information on installation, lubrication, adjustments, operating instructions, wiring diagrams, and exploded view diagrams of the parts with descriptions. Please see contents below:

|

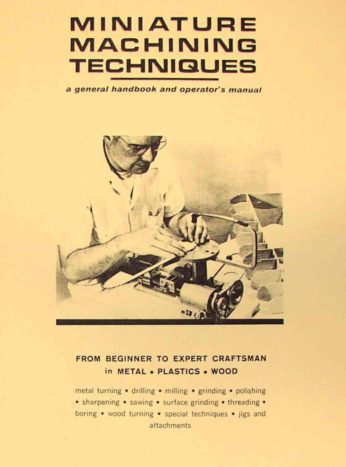

The manual above may help you operate and maintain your metal lathe. If you would like to learn more about metal lathework techniques, the names and proper uses of different lathe tools, and other lathe operations, I would recommend clicking on the pictures of these two books here. We also have a complete series of different machinist books on sharpening, gearmaking, milling machines, and more here: Workshop Machinist Series |

|

|

|---|

Contents:

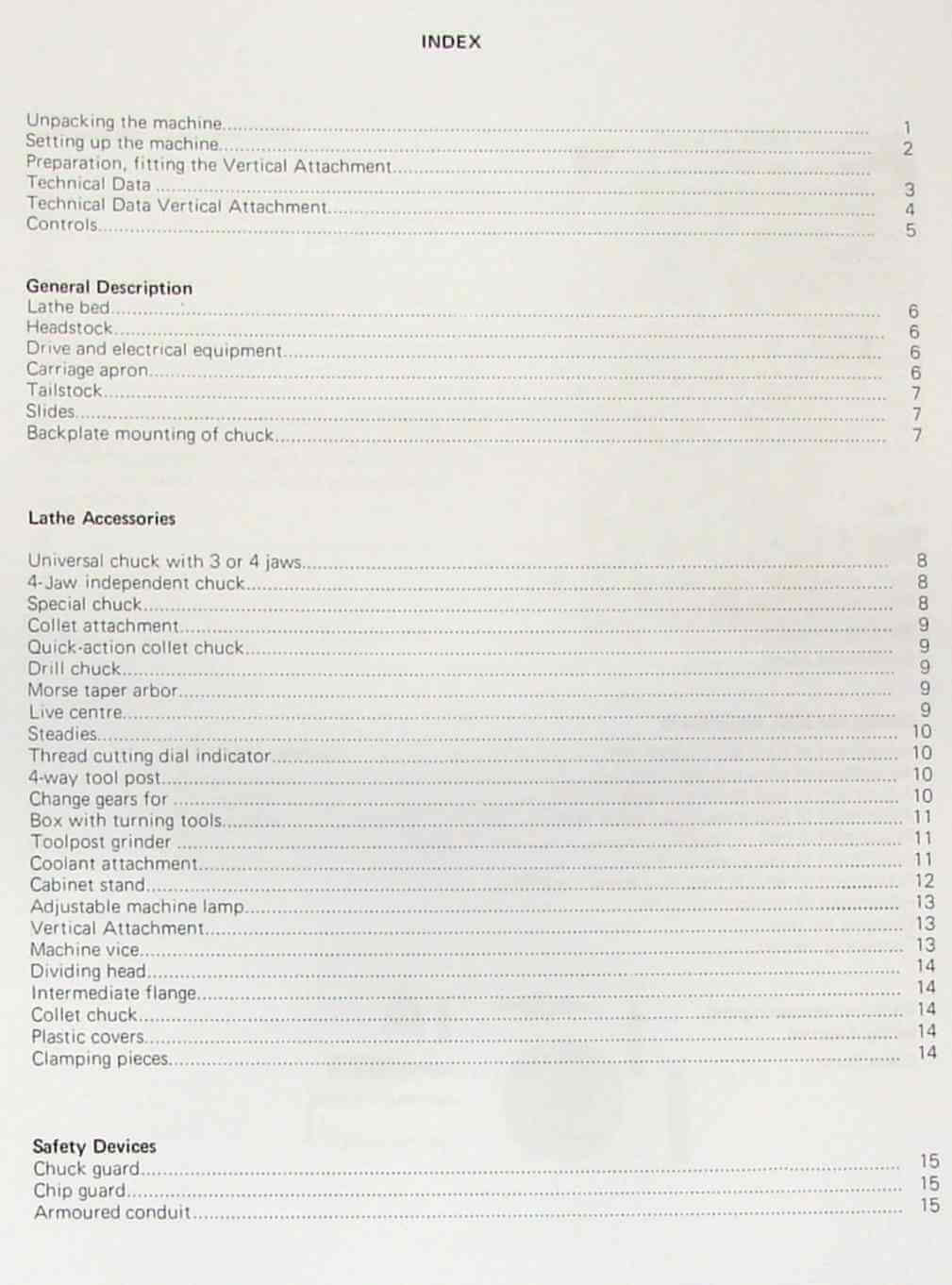

Unpacking the machine...................................1 Setting up the machine..................................2 Preparation, fitting the Vertical Attachment............2 Technical Data..........................................3 Technical Data Vertical Attachment......................4 Controls................................................5 General Description Lathe bed...............................................6 Headstock...............................................6 Drive and electrical equipment..........................6 Carriage apron..........................................6 Tailstock...............................................7 Slides..................................................7 Backplate mounting of chuck.............................7 Lathe Accessories Universal chuck with 3 or 4 jaws........................8 4-Jaw independent chuck.................................8 Special chuck...........................................8 Collet attachment.......................................9 Quick-action collet chuck...............................9 Drill chuck.............................................9 Morse taper arbor.......................................9 Live centre.............................................9 Steadies...............................................10 Thread cutting dial indicator..........................10 4-way tool post........................................10 Change gears for.......................................10 Box with turning tools.................................11 Toolpost grinder.......................................11 Coolant attachment.....................................11 Cabinet stand..........................................12 Adjustable machine lamp................................13 Vertical Attachment....................................13 Machine vice...........................................13 Dividing head..........................................14 Intermediate flange....................................14 Collet chuck...........................................14 Plastic covers.........................................14 Clamping pieces........................................14 Safety Devices Chuck guard............................................15 Chip guard.............................................15 Armoured conduit.......................................15 Working with EMCO Universal machines and accessories Taper turning using the tailstock set..................16 Taper turning using the top slide......................16 Quick - action collet chuck............................17 Fixed steady...........................................17 Travelling steady......................................18 Selecting and mounting change gears....................18 for thread cutting.....................................18 Turning with automatic feed............................19 Working with the toolpost grinder...................20,21 Tool mounting and removal on the.......................22 Vertical spindle.......................................22 Setting constant drilling depth........................23 Working with the dividing head...................23,24,25 Tables Indexing...............................................26 Material cutting chart.................................27 Cutting speeds for lathe and vertical spindle..........27 Pitch and feed chart...................................28 Working examples....................................29,30 Lubrication chart......................................31 Bearing and Slide Adjustments Adjustment of main spindle bearings....................32 Adjustment of cross and top slides.....................32 Adjustment of feed screw end float.....................32 Adjustment of feed screw blacklash in nuts.............32 Adjustment of half-nut guide...........................33 Adjustment of lead screw blacklash.....................33 Adjustment of vertical head feed screw blacklash.......33 Adjustment of vertical head guide......................34 Changing the belt......................................34 Tensioning the belt....................................34 Electrical connecting and wiring diagrams

Overview

I have collected this information for many years and have found the information they contain to be priceless in using and setting up the machines properly. I believe this manual will be a valuable resource of knowledge that will provide a lot of helpful information that is often hard to find. My manuals are not photocopies. I maintain a high standard of quality in my reproductions. Most of the manuals I reproduce look better than their originals. I have professionally digitally edited every page, and removed stains, wrinkles and handwriting. All of the manuals are printed on thick white paper to withstand shop wear and tear; they are then comb bound with heavy cover pages so they lie flat on the workbench.